Years Experience

ISM Mould was established in 2009 . Our core focus is professional design and manufacture of all kinds of plastic pallets , folding boxes, crate and other plastic logistics products mold .

We insist on the principle of “ satisfying customers” demands and realizing the idea with professional solutions”. As a result of our ongoing development , ISM has a team of highly skilled designers , engineers , project managers , fabrication technicians and advanced large-scale precision machining equipment that ensures these injection molds manufactured by ISM are produced according to European and North American standards .

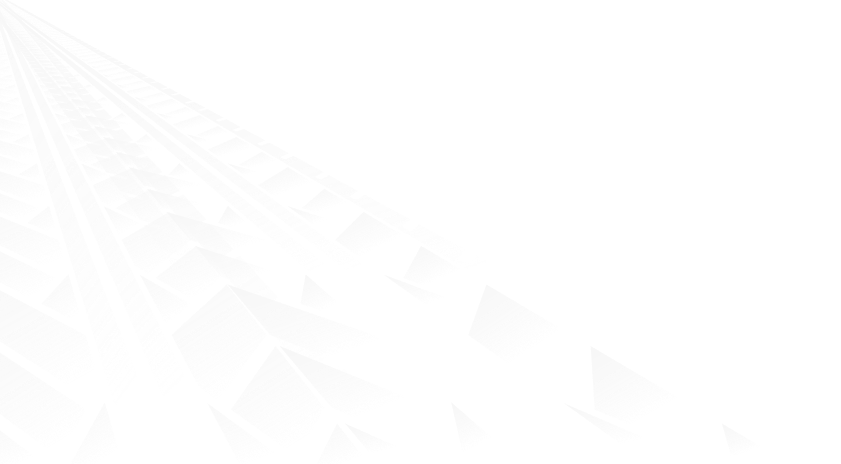

Ism is China's leading plastic crate mould manufacturer, we provide design, manufacturing, and sales services for plastic crate mould. Contact with ISM , we will provide you with the most complete service from the design to the production of plastic crate mould.

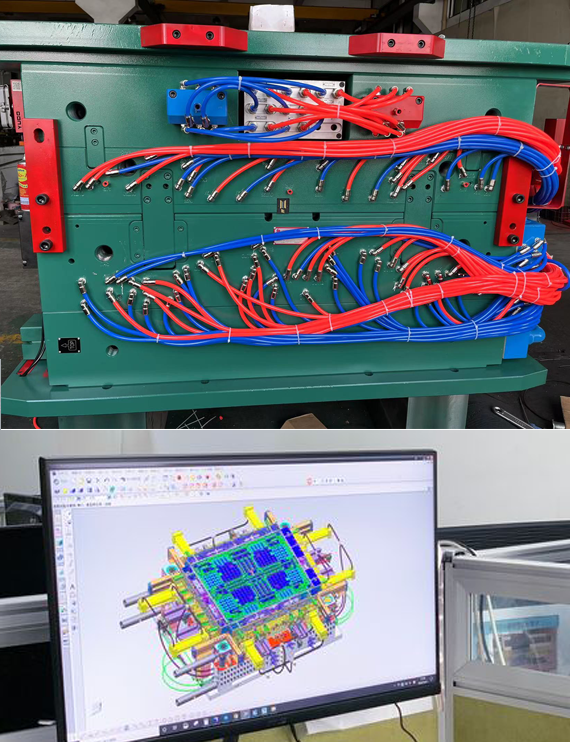

ISM is a professional manufacturer of plastic pallet molds ,For more than a decade we have worked with many world class plastic pallet manufacturer , and through such collaboration we continuously improve our technologies and process . Single-sided pallet , double-sided pallet , gas-assisted pallet and so on

The injection pallet molds developed by our company have the advantages of high difficulty , long life ,short cycle time , reasonable price , prompt delivery and considerate service ,especially in the field of injection molds , which are favored by customers at home and abroad .

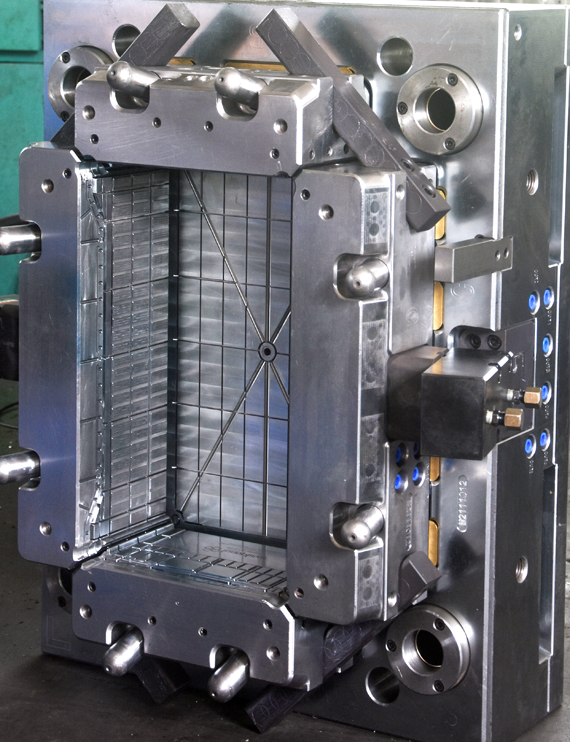

As China injection crate mould company , ISM provides various injection crate mould solutions , and has an advanced technologies of cooling system design skills .

ISM Mould is your best choice for plastic chair mould supplier China. We can offer you 2D and 3D design of plastic chair mould, we can make a modification with your design according to your special requirement, we can make plastic chair mould for you and help you product plastic chair mould and then ship them to you.

we has developed more than 200 sets various chair moulds during these years, such like rattan design outdoor chair mould, beach chair mould, rattan plastic chair mould,outdoor chair injection molds,stackable plastic chair moulds,folding chair injection mould manufacturer,office injection moulded chairetc.

ISM Mold focuses on the manufacture and development of chair molds, and pays attention to the selection and location of chair mold steel, cooling system, parting line, wall thickness, venting, etc. Welcome to contact us for more detail.

Focus on Overall Quality

Focus on Overall Quality

International Standard Mould

We Have More Than 16+ Years Of Mould Make Experiences

Call Us Any Time 24/7:

(+86)13676642643Every project are led by a project manager who oversees project specifics, logistics, and schedule.Keep in touch with you to understand the progress of the mold.

We've established a quality management system as required by international certifications, created documentation and constructed a system for our company.

Our quality control process is a technological approach with consistent monitoring of quality throughout the manufacturing process.

FAQ’s

FAQ’s

We usually use Chinese brand steel. Such as general furniture molds and daily necessities molds, we will use P20 steel; Chair, turnover box or Pallet Mould and other finer product molds use 718H. In addition, we will also use imported German steel according to customer requirements.

We use AutoCAD software for 2D drawings, and UG, CATIA, Pro-E software for 3D drawings.

Before mold production, we will send 2D/3D product modelling drawings and mold structure design drawings to customers for confirmation.

Our annual production capacity is 600 sets and more, including 300 plastic chair molds and 200 turnover box molds...

Our News Update

Our News Update