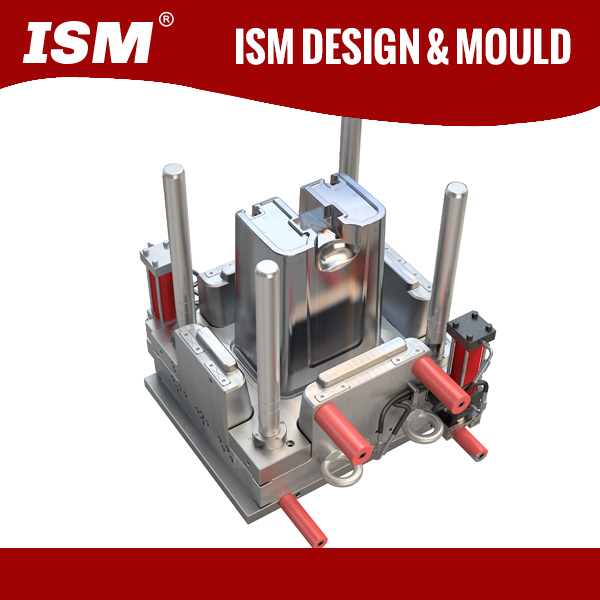

All of ISM customer molds are built right here inside of our China Taizhou facility. Our mold build area is staffed with experienced designers and machinists using the most modern software and CNC machinery. After customer part designs are finalized and approved for manufacturing our team will design and build robust trouble free plastic injection molds for your production.

| Items | Description |

|---|---|

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Hardness of steel | 46~56 HRC |

| Molud Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mould Base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| Cavity | Single/Multi |

| Runner | Hot/Cold Runner |

| Maximum Mould Size | 1500*1500 mm |

| Surface of Mould | EDM / High Polish&Texture |

| Plastic material | PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,HIPS, PMMA etc. |

| Mould Life | 300,000-1,000,000 shots |

| Specification | Depends on customer’s requirements. |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

| Trade terms | FOB Shenzheng,EXW ,CIF |

| Export to | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Surface finish of Part | Logo print,Texture,Polishing,Painting,Chrome Plating |

| Delivery time | 20-35 Days |

| Outside package | Standard wooden casesor as your requirement |

| Inner package | Stretch waterproof film & Each Mold painted ,anti-rust oil.3. Spare parts together with the mold shipment. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Items | Description |

Reviews