Product Name |

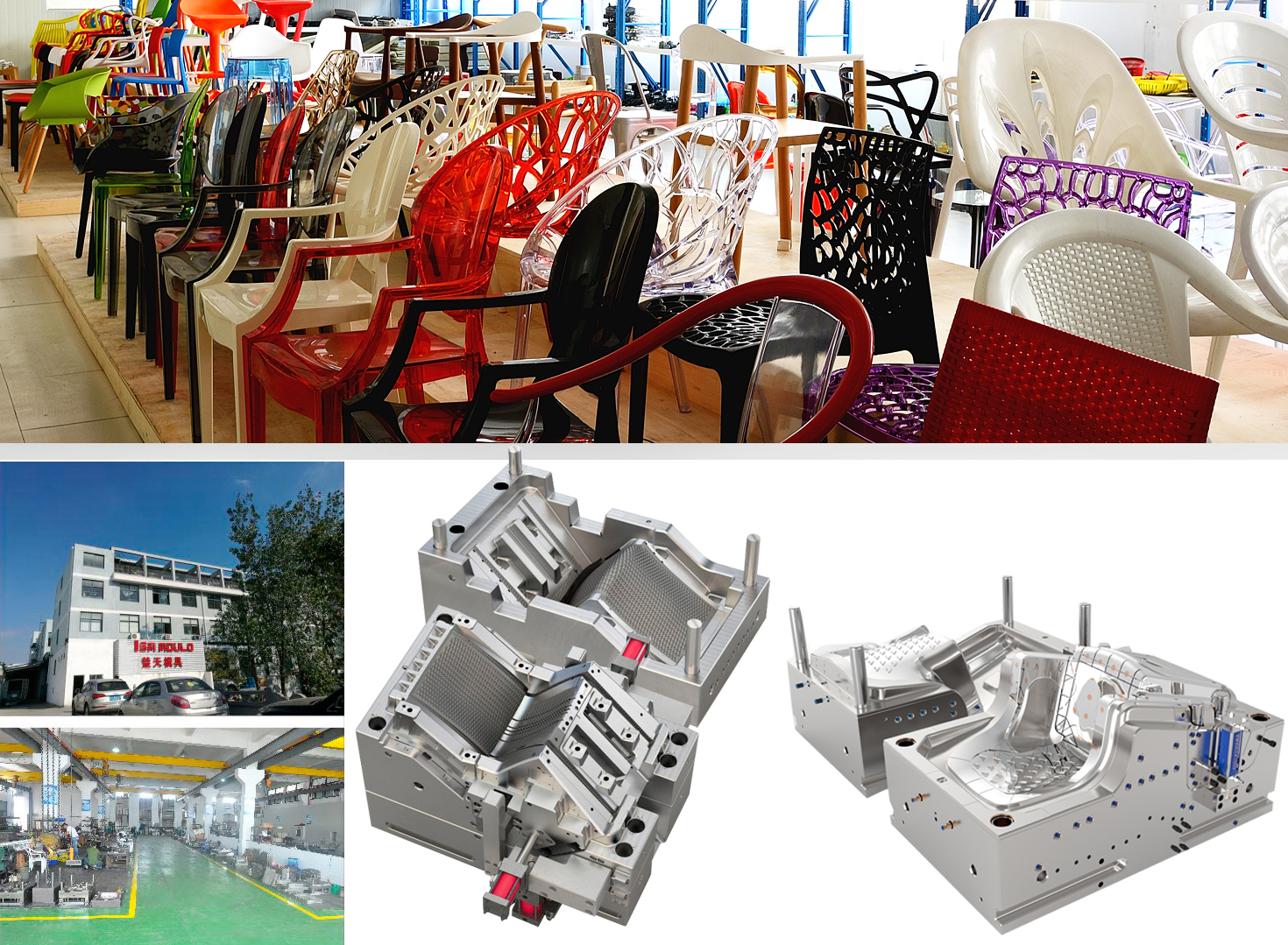

Morden style moulds office moulded foam shell eames rattan soffa baby manual mould chair |

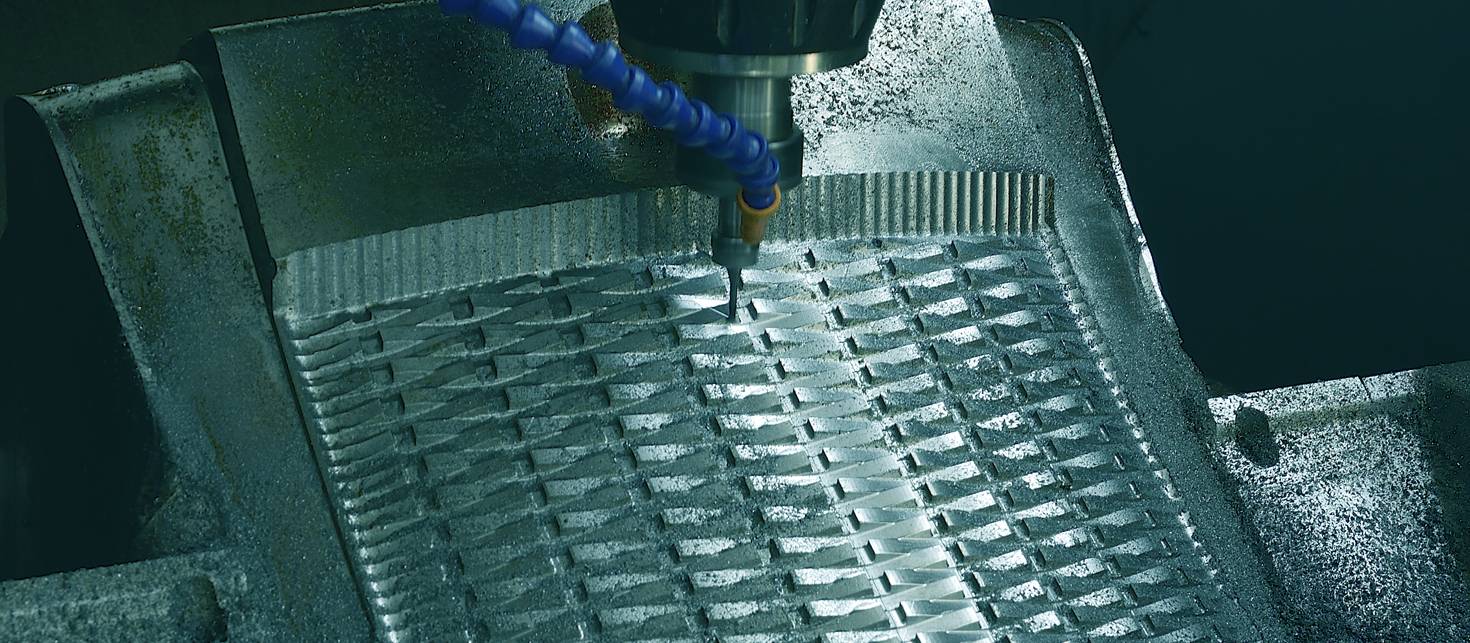

Core & Cavity Steel |

2316# steel, S136, H13,718,SKD61,P20,S50C,45#steel,4Cr13, 3Cr13, Becu or based on customer's requirement |

Mould base & Standard Component |

P20, 4cr13, h13.718 |

Steel hardness |

HRC30-35 for base material; HRC45-48 for core and cavity material; HRC60-62 for special parts material |

Plastic material |

PP,PC,PA,PA6,ABS,PET,PVC,POM,etc |

Cavity Number |

1*4 1*6 1*8 1*2 etc |

Injection System |

Pin gate, Submarine gate, Valve gate etc. |

Cycle Time |

Based on design |

Tooling lead time |

30-60 days |

Mould life |

At least 1.5 million shots |

Transportation |

By air or by sea |

Looking for a reliable Chair mold supplier in China? We offer a one-stop solution for all your chair mould needs, and we’re committed to quick delivery and outstanding customer service. With over 16 years of experience in the industry, we know how to get the job done right.In a Plastic chair mould market that is increasingly competitive, ISM shines as a reliable one-stop supplier of chair molds.

2024/4/15 , visits

Reviews