Plastic Pallet Molds: Advantages, Disadvantages, and Key Considerations

Introduction

Plastic

pallets have revolutionized logistics and material handling, offering

durability, hygiene, and efficiency advantages over traditional wood. At

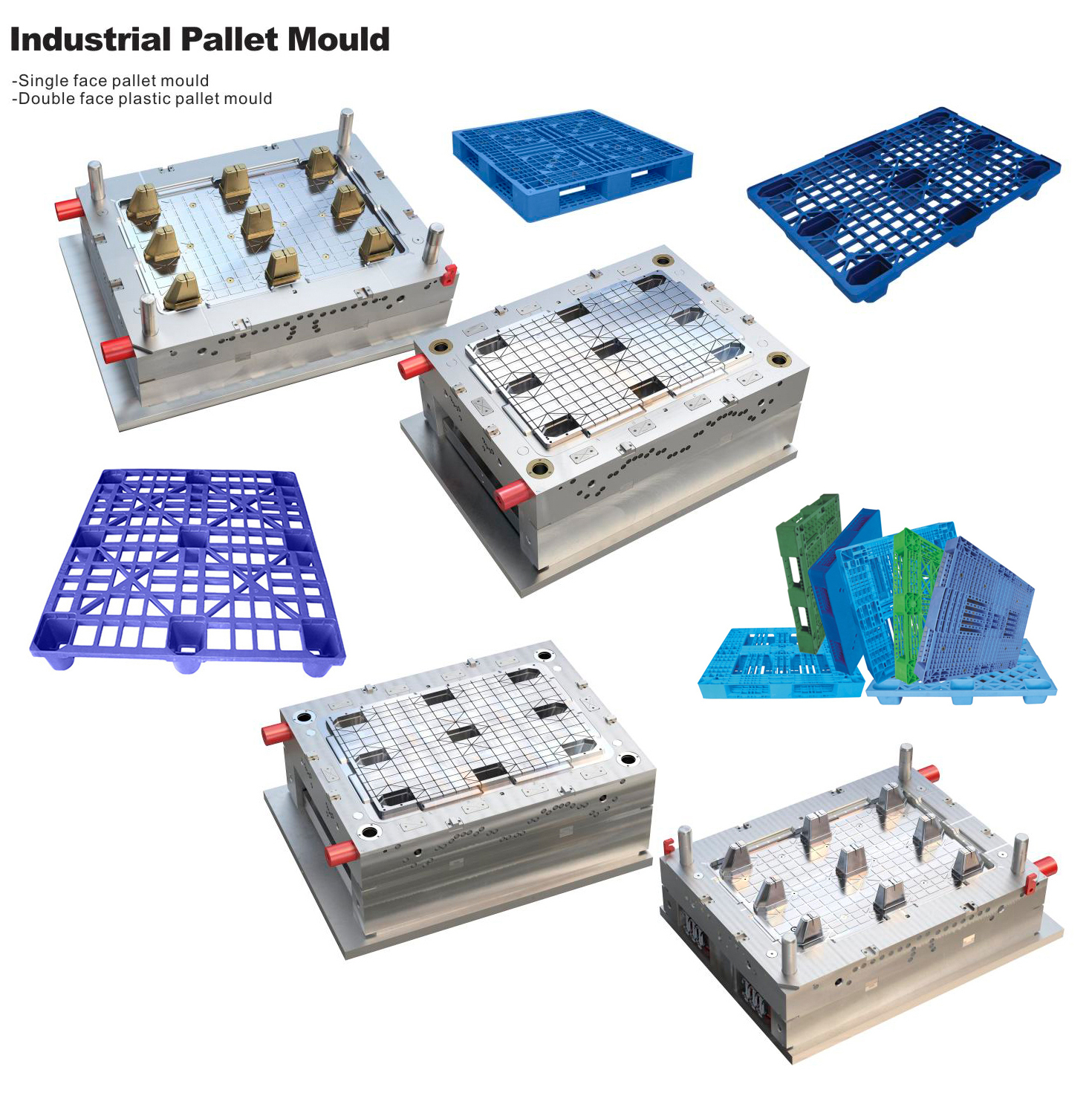

the heart of mass-producing these essential platforms lies the plastic pallet mold. Typically manufactured via injection molding,

these molds are precision-engineered tools defining the pallet's final

form, strength, and features. Understanding the pros and cons of plastic pallet mold design and manufacturing is crucial for businesses investing in pallet production or sourcing.

Advantages of Plastic Pallet Molds

High Production Efficiency & Repeatability:

Once the injection mold is built and optimized, it enables incredibly fast cycle times. Thousands of identical, high-quality pallets can be produced rapidly with minimal variation.

Automated production is seamless, reducing labor costs and boosting output for high-volume pallet manufacturing.

Keywords: injection molding process, high-volume production, automated pallet manufacturing, consistent quality, fast cycle times.

Superior Product Consistency & Quality:

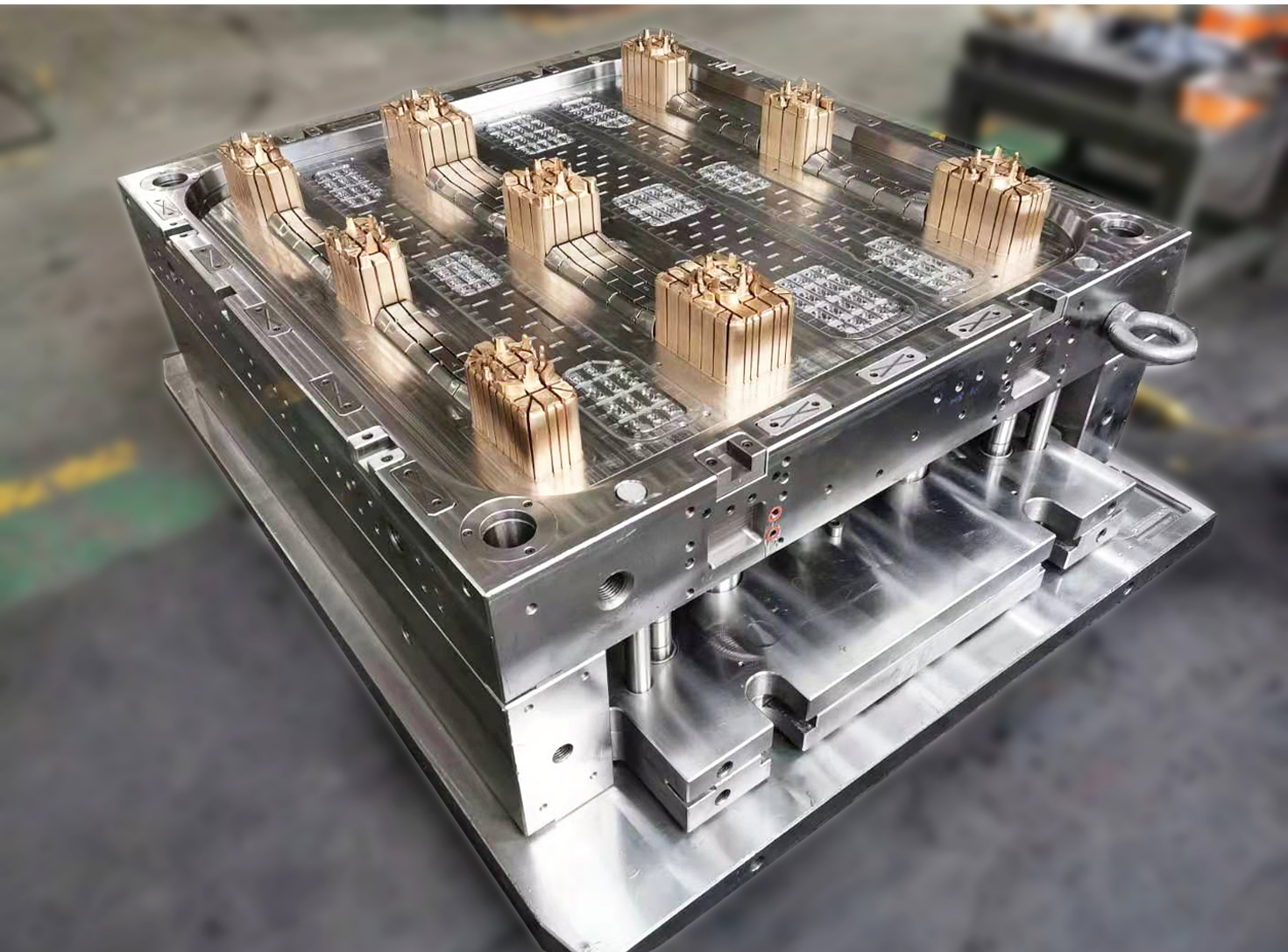

Precision-machined mold tooling ensures every pallet produced has identical dimensions, weight distribution, strength characteristics, and surface finish.

Eliminates defects common in wood (splinters, nails, warping) and ensures reliable performance in automated systems (like AS/RS).

Keywords: precision mold tooling, consistent pallet dimensions, reliable pallet performance, automated warehouse compatibility, high-quality plastic pallets.

Design Flexibility & Complexity:

Mold design allows for intricate features impossible with other methods: complex rib structures for strength-to-weight optimization, integrated anti-slip surfaces, logos, stacking lugs, drainage channels, and specific leg designs (e.g., 4-way entry, 2-way entry, nestable, rackable).

Facilitates custom plastic pallet solutions tailored to specific load requirements, industry regulations (e.g., FDA, EPAL), or handling equipment.

Keywords: custom pallet mold, complex pallet design, optimized strength-to-weight ratio, integrated features, nestable pallets, rackable pallets, FDA pallet mold.

Material Efficiency & Sustainability:

Injection molding produces minimal waste (runners and sprues can often be reground and reused).

Allows for precise control over material distribution within the pallet structure, optimizing weight and cost.

Enables the use of recycled plastic resins (rPP, rHDPE), contributing to sustainable pallet solutions and circular economy goals.

Keywords: material efficiency, recycled plastic pallets, sustainable packaging, minimal waste, regrind usage, optimized material distribution.

Long Tool Life & Durability:

High-quality steel molds, properly maintained, can last for hundreds of thousands, even millions, of cycles.

Represents a significant long-term asset for pallet manufacturers, amortizing the initial investment cost over vast production volumes.

Keywords: durable steel molds, long mold lifespan, high cavitation molds, mold maintenance, pallet manufacturing investment.

Disadvantages of Plastic Pallet Molds

High Initial Investment Cost:

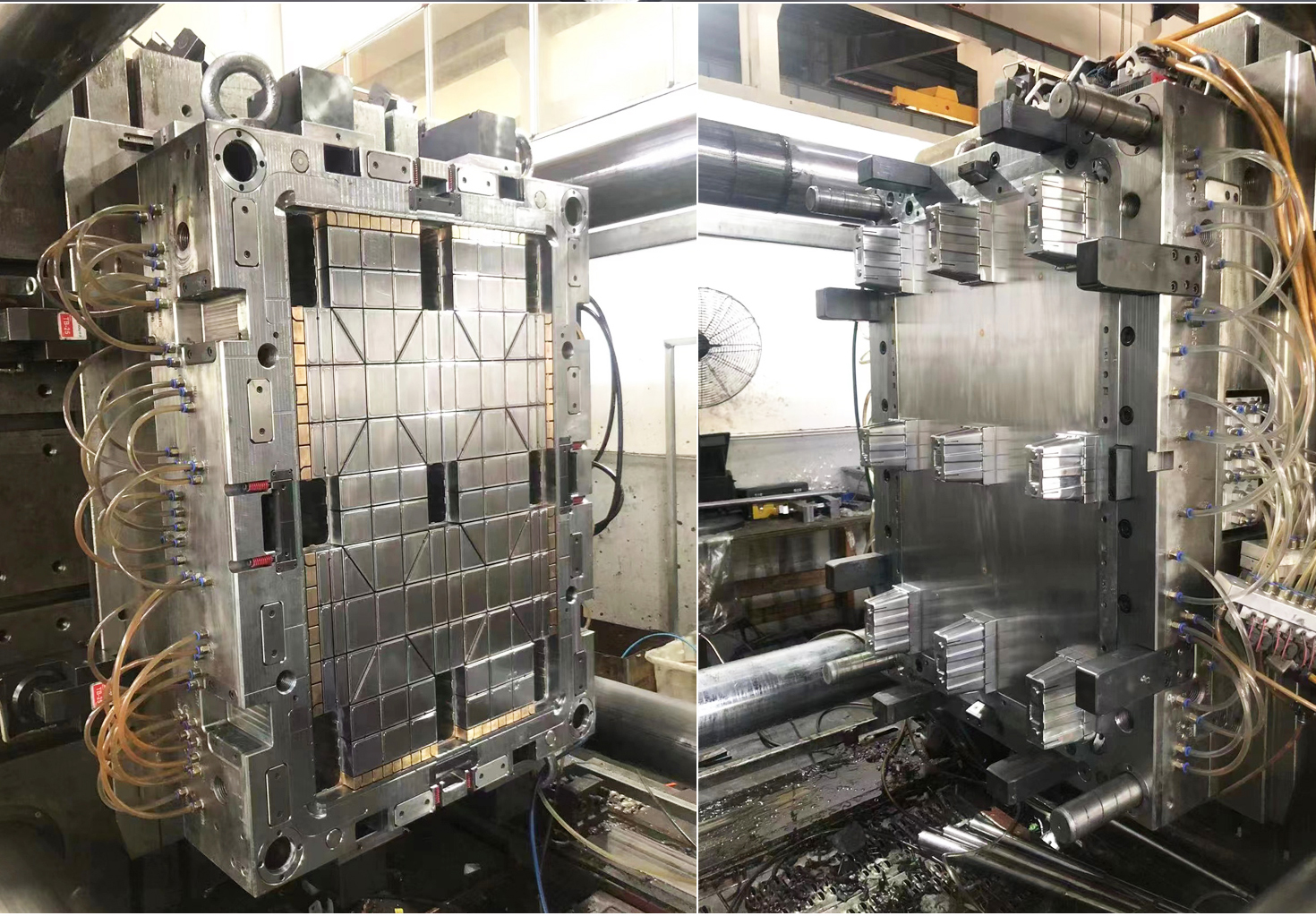

Designing, machining, and finishing a complex plastic pallet mold requires significant expertise, time, and expensive materials (hardened steel). Costs range from tens of thousands to hundreds of thousands of dollars.

This high upfront cost is a major barrier, especially for small businesses or low-volume production runs. ROI calculation is essential.

Keywords: high mold cost, expensive tooling, upfront investment, ROI for pallet molds, capital expenditure.

Long Lead Times for Development:

Mold design, machining, testing, and refinement can take several weeks to months before production-ready pallets are made.

This requires careful planning and delays the time-to-market for new plastic pallet designs.

Keywords: mold design time, mold manufacturing lead time, prototyping pallets, time-to-market delay.

Design Complexity & Rigidity:

Once the mold is built, making significant design changes is extremely costly and time-consuming, often requiring new tooling or major modifications.

Design flexibility exists before mold cutting; it becomes rigid afterward. Thorough prototyping and testing are critical before mold commitment.

Keywords: design inflexibility, mold modification cost, prototype pallet testing, final design freeze.

Maintenance Requirements & Downtime:

Molds require regular mold maintenance – cleaning, lubrication, inspection for wear or damage (especially on critical surfaces like cores, cavities, and slides).

Wear over time can affect part quality (flash, dimensional drift). Repairing or refurbishing molds incurs costs and causes production downtime.

Keywords: mold maintenance cost, tooling downtime, mold repair, wear and tear, production stoppage.

Limited Viability for Very Low Volumes:

The high fixed cost of the mold makes injection molding economically unfeasible for very small production quantities. Alternative processes like structural foam molding or thermoforming might be considered, but they have different mold characteristics and limitations.

Keywords: low-volume production, mold cost amortization, alternative pallet manufacturing, structural foam molding, thermoforming pallets.

Conclusion

The plastic pallet mold is the cornerstone of efficient, high-quality pallet production. Its advantages in speed, consistency, design capability, and long-term durability are unparalleled for high-volume pallet manufacturing. However, the significant upfront investment, lead time, and design inflexibility demand careful consideration. Businesses must realistically assess their production volume needs, budget constraints, and design requirements before committing to injection mold tooling.

Choosing an experienced mold manufacturer with expertise in pallet mold design and durable steel molds is critical to maximizing the benefits and minimizing the risks associated with plastic pallet molds. For operations requiring large quantities of consistent, durable, and feature-rich pallets, the advantages of a well-designed and maintained mold far outweigh the initial disadvantages, delivering a powerful and cost-effective solution for the global supply chain.

Leave a Reply

Your email address and tel will not be published. Required fields are marked