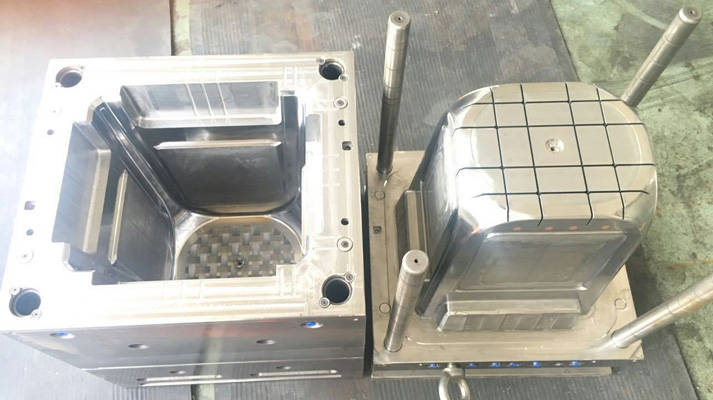

Stool mold square stool mold round stool mold professional manufacturer price

Plastic Stool Mould

Designers must understand that, whether the cavity is gated at the edge or near the center of the stool product, most or all of the plastic will flow toward the parting line.

Advantage 1: The molding time of the stool mold is shortened

Because there is no limitation on the cooling time of the runner system, the parts can be ejected in time after they are formed and solidified. Many mold molding cycles produced by hot runner molds can be less than 5 seconds.

Advantage 2: Save the production cost of the stool mold

Because there is no cold runner in the pure hot runner mold, there is no production cost, which is especially important for the application projects with expensive plastics.

In fact, the major manufacturers of warm runners in the world have developed rapidly in the era when petroleum and plastic raw materials are expensive in the world. Because this technology has played a great role in many fields, not only in Stool mold this piece.

Advantage 3: greatly simplify the follow-up process of stool mold production

After being formed by the hot runner mold, the workpiece is a finished product, and there is no need to trim the gate and reprocess the cold runner, which is conducive to production automation. Many foreign product manufacturers combine warm runners with automation to greatly improve production efficiency.

Plastic Stool Mould

cavity:1

Hotrunner:1 drops with “HOTSET” heating coils

plastic stool mould cavity steel:P20

plastic stool mould core steel:P20

Plastic material:PP

Cycle time:40 Secs

Delivery time:35 day

The air that was inside the cavity space before the mold was clamped up must now escape to

permit easy filling of the cavity,

prevent burning of the leading edge of the plastic, or

eliminate the possibility of unfilled spots forming in the product.

Leave a Reply

Your email address and tel will not be published. Required fields are marked