Your Trusted OEM Crate Mould Partner

1. Design & Prototyping

The process begins with 3D CAD/CAM/CAE design, where engineers collaborate with clients to create blueprints tailored to specific crate dimensions, load-bearing requirements, and material flow analysis. Advanced software ensures precision, addressing potential defects like sink marks or warping early in the design phase 510. Prototypes are developed using CNC machining or 3D printing for validation, ensuring functionality before mass production.

SEO Keywords: Custom Crate Mould Design, CAD/CAM Prototyping, Precision Engineering

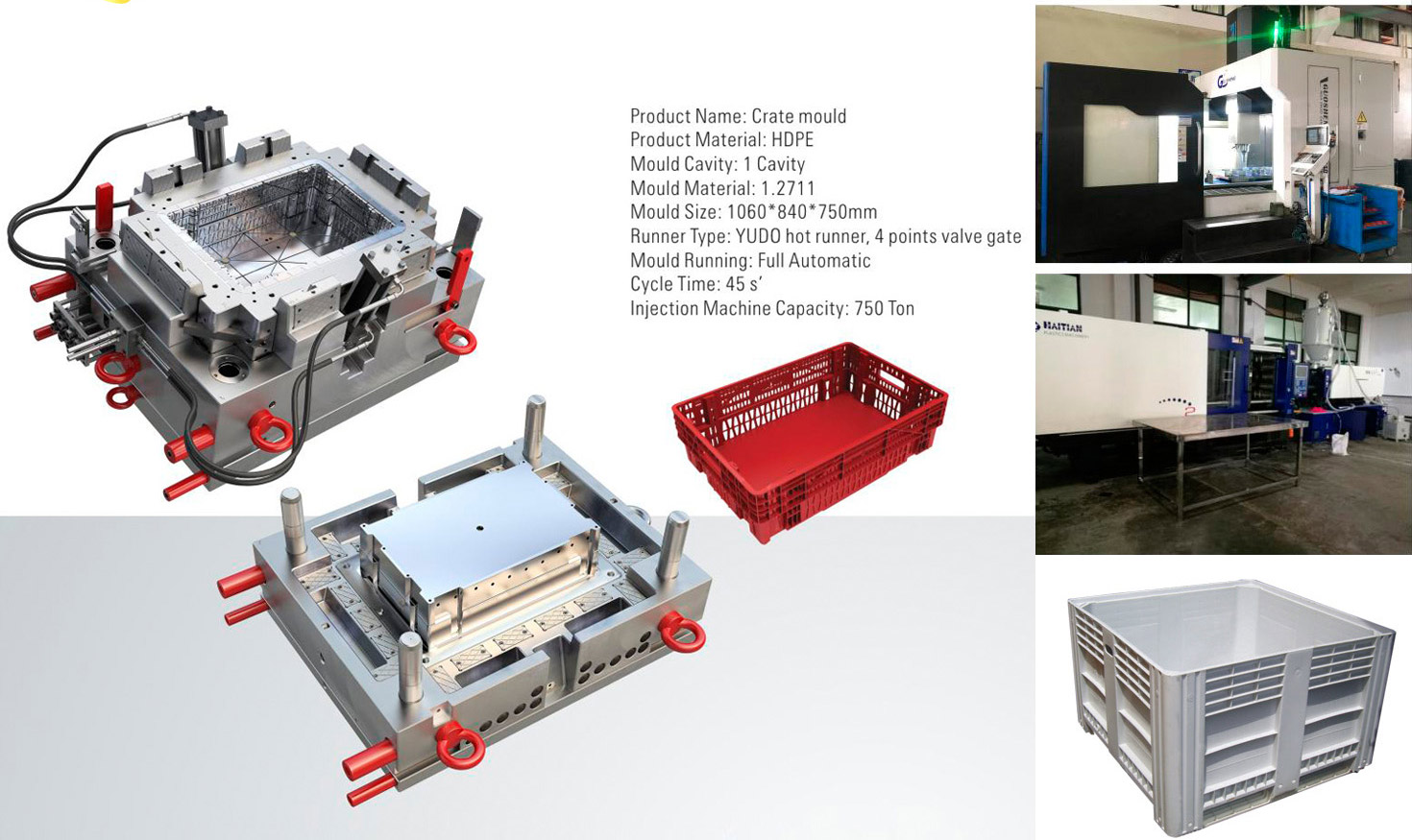

2. Material Selection

High-performance materials such as tool steel (DME/HASCO standard), HDPE, PP, or ABS are chosen based on durability, environmental factors, and application needs. For heavy-duty crates, reinforced steel alloys or wear-resistant plastics are prioritized. Suppliers emphasize FDA/CE-compliant materials for food-safe or medical applications 510.

SEO Keywords: FDA-Compliant Mould Materials, HDPE Crate Mould, Tool Steel Moulds

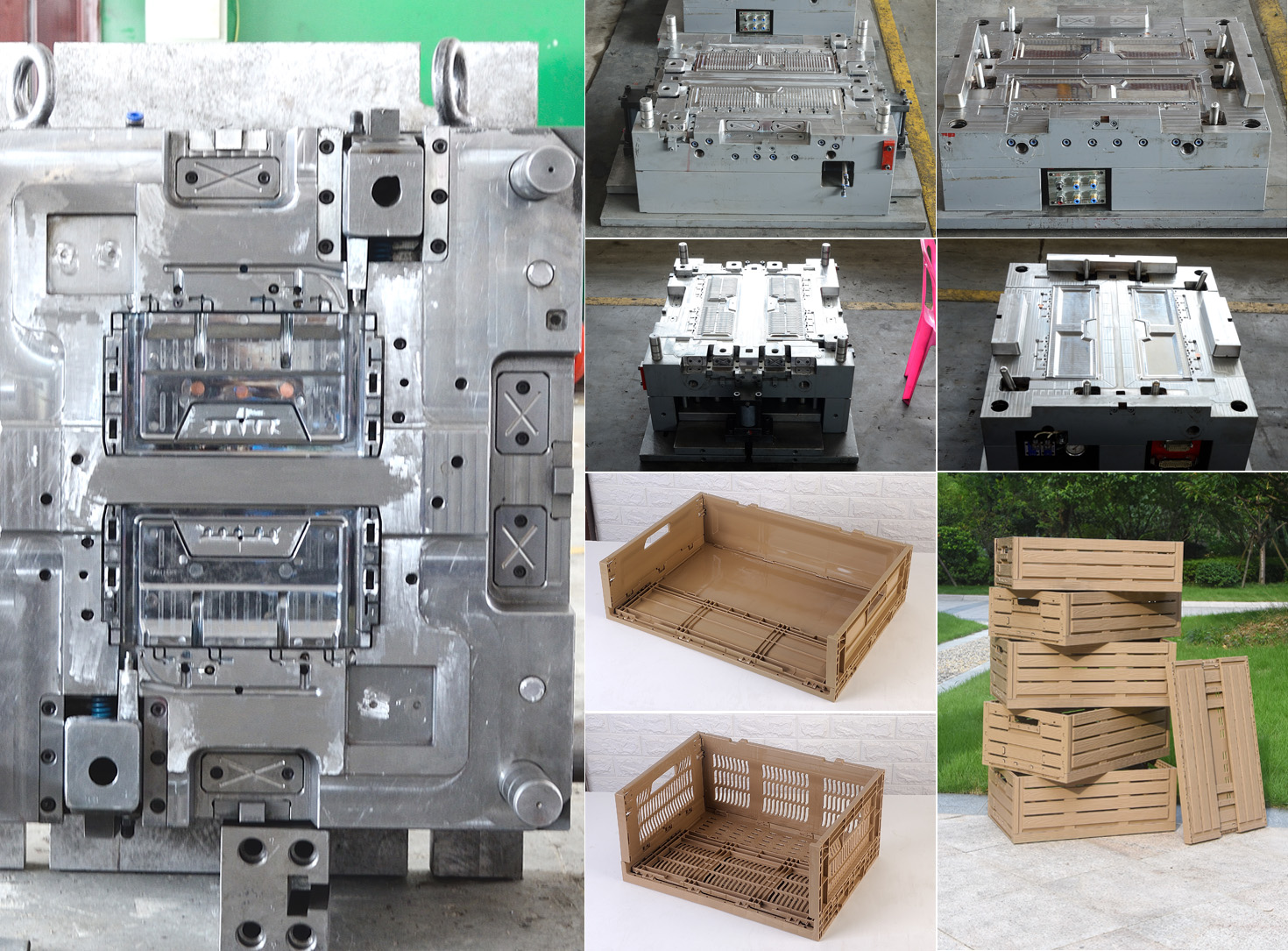

3. Precision Manufacturing

Moulds are crafted using state-of-the-art equipment, including CNC machining centers, EDM (electrical discharge machining), and slow wire cutting to achieve tolerances as tight as 0.01mm. For high-volume production, multi-cavity or hot-runner systems are integrated to reduce cycle times and material waste. Companies like Taizhou Huangyan ISM Mould Co., Ltd. specialize in plastic crate moulds with reinforced structures for enhanced load capacity 210.

SEO Keywords: CNC Machining Moulds, Hot-Runner Systems, High-Volume Mould Production

4. Quality Control & Testing

Rigorous inspections are conducted at every stage, including DFM (Design for Manufacturability) analysis, mold flow simulations, and real-world stress tests. Final products undergo AI-driven inspections and are certified with steel quality reports, heat treatment records, and dimensional accuracy checks 510. For example, PTJ TECH employs ISO 9001-certified processes to ensure compliance with global standards.

SEO Keywords: Mould Quality Assurance, ISO-Certified Manufacturing, DFM Analysis

5. Surface Treatment & Customization

Post-production services include texturing, polishing, or chrome plating to meet aesthetic or functional requirements. Secondary processes like pad printing, silk-screen logos, or laser engraving are offered for brand customization. Suppliers such as Wonder Moulds provide overmolding and thin-wall molding for complex designs 105.

SEO Keywords: Custom Surface Finishing, Branded Crate Moulds, Overmolding Solutions

6. Sustainability & Efficiency

Leading manufacturers adopt eco-friendly practices, such as recyclable materials and energy-efficient machinery, to minimize carbon footprints. For instance, Guangdong WinSton Technology utilizes waste-reduction processes and biodegradable plastics for sustainable crate solutions 210.

SEO Keywords: Eco-Friendly Mould Manufacturing, Sustainable Plastic Moulds, Green Production

Why Partner with China OEM Suppliers?

-

Cost Savings: Leverage China’s supply chain advantage for 30–50% lower costs compared to Western counterparts 25.

-

Scalability: Flexible MOQs from 500 to 1M+ units, supported by factories with 10+ production lines 210.

-

Global Logistics: Doorstep delivery with real-time tracking and expedited shipping options 5.

Conclusion

China’s OEM crate mould suppliers combine advanced technology, cost-effectiveness, and customization to deliver solutions for logistics, agriculture, and retail industries. With certifications like ISO 9001 and expertise in plastic injection moulding, they ensure durability, precision, and sustainability. Explore partnerships with trusted manufacturers to optimize your supply chain today.

SEO Keywords: China OEM Crate Mould Suppliers, Plastic Injection Moulding Services, Custom Mould Manufacturing

Leave a Reply

Your email address and tel will not be published. Required fields are marked