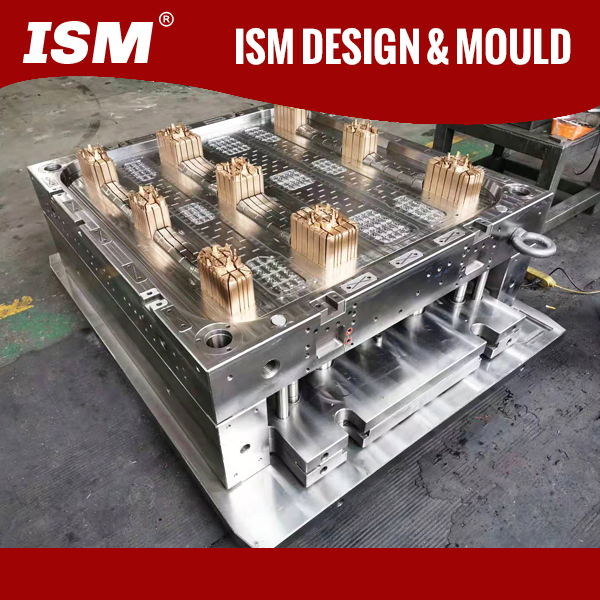

Plastic Pallet Mould Manufacturer Factory | High-Durability Molds for Logistics & Industrial Solutions

Introduction: Precision Molds Powering Modern Logistics

Plastic pallets have revolutionized global supply chains, offering lightweight, hygienic, and reusable alternatives to traditional wooden pallets. As a leading plastic pallet mould manufacturer factory, we engineer robust, high-precision molds that empower industries to produce pallets for logistics, warehousing, pharmaceuticals, and food processing. With advanced technology and decades of expertise, we deliver molds that maximize productivity, durability, and ROI for businesses worldwide.

Why Partner with a Professional Plastic Pallet Mould Factory?

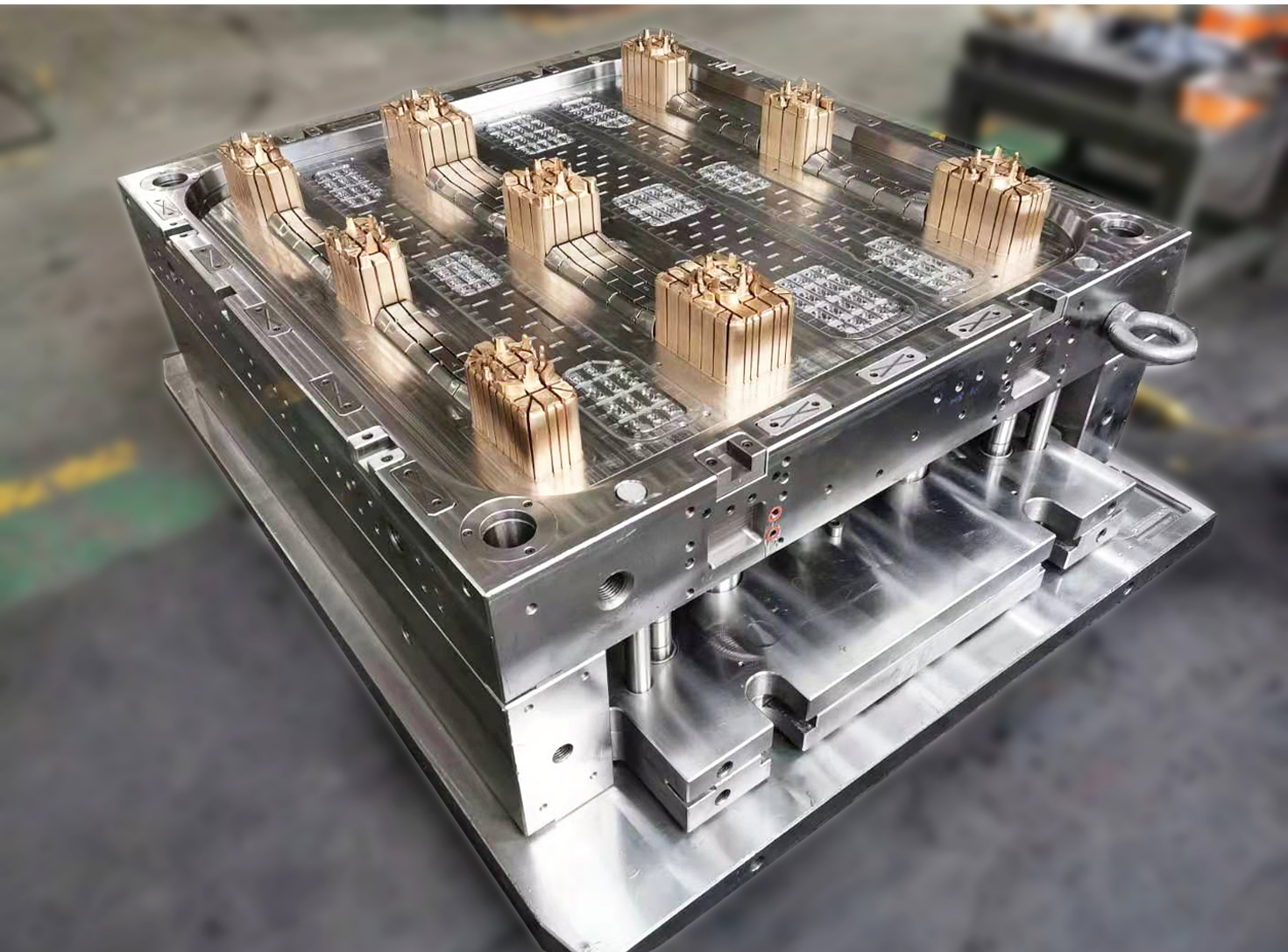

1. Cutting-Edge Technology for Superior Mold Performance

Smart Design & Simulation:

Using CAD/CAE software (e.g., SolidWorks, Moldflow), we optimize mold structures for uniform cooling, minimizing warpage and achieving dimensional accuracy within ±0.03mm.High-Precision Machining:

Equipped with 5-axis CNC machines, EDM, and wire-cutting technology, we produce mold cores with surface roughness below Ra 0.2μm, ensuring smooth demolding and mold lifespans exceeding 1 million cycles.Multi-Material Adaptability:

Design molds for HDPE, PP, recycled plastics, and reinforced composites, meeting ISO 6780, FDA, and EU food-grade standards.

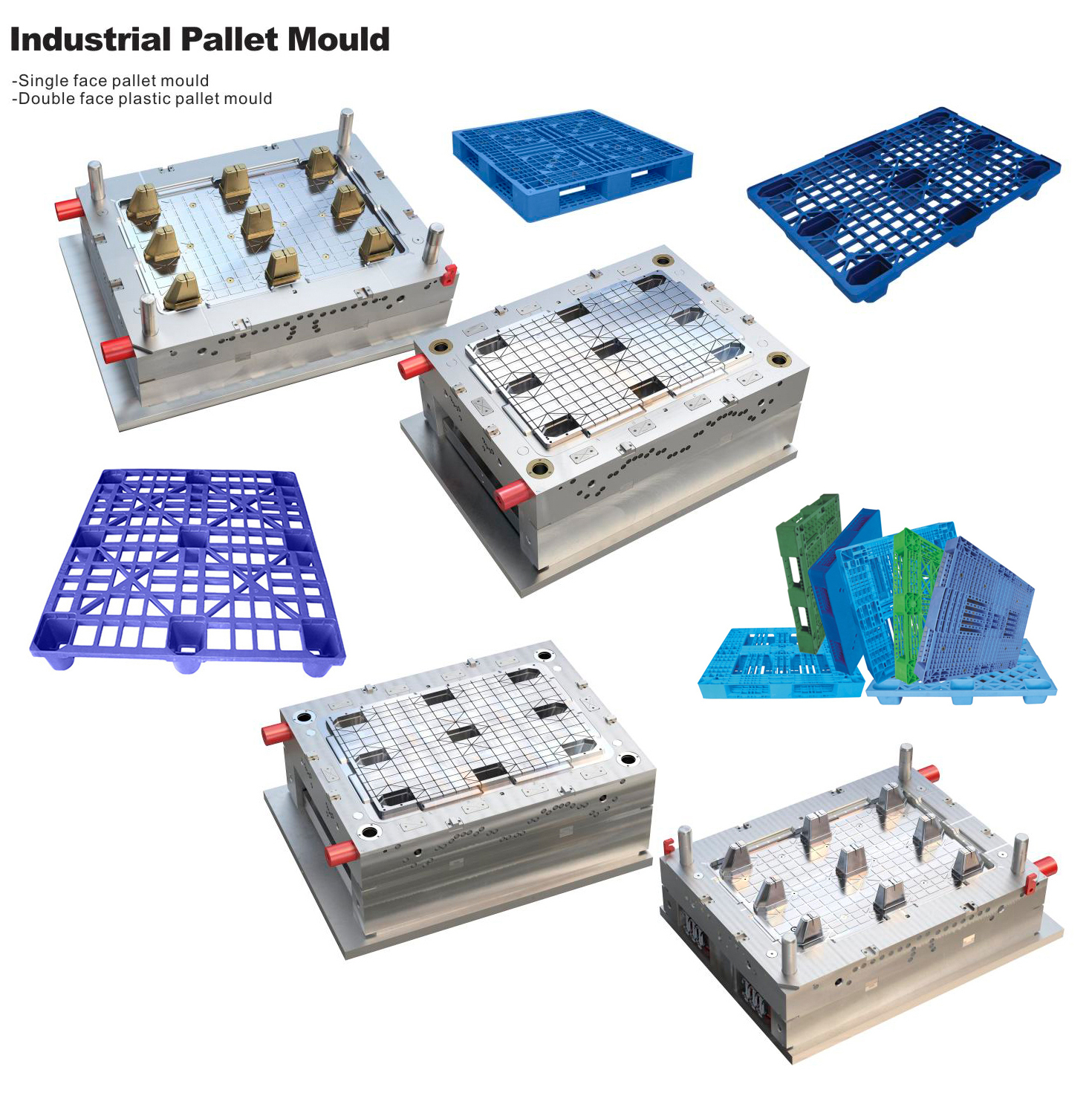

2. Customized Solutions for Diverse Industry Needs

We tailor molds to produce pallets for specific applications:

Pallet Types: Nestable, rackable, four-way entry, double-sided, and anti-slip designs.

Load Capacity: Static loads up to 15,000 lbs and dynamic loads of 3,000–5,000 lbs for heavy-duty logistics.

Industry-Specific Features:

Food & Pharma: Hygienic, non-porous surfaces with antimicrobial coatings.

Automotive: Flame-retardant and anti-static pallets for electronic components.

Export Logistics: Lightweight designs to reduce shipping costs.

3. Rapid Prototyping & Scalable Production

3D-Printed Samples: Deliver functional prototypes in 5–7 days for design validation.

Short Lead Times: Mass production molds ready in 20–30 days (standard projects).

Global Compliance: Support EUR/EPAL, GMA, and custom specifications for seamless integration.

Quality Assurance: Building Trust Through Rigorous Standards

Certifications: ISO 9001:2015, ISO 14001 (environmental management), and IATF 16949 for automotive-grade molds.

Testing Equipment: CMM (Coordinate Measuring Machines), impact testers, and dynamic load simulators.

Material Traceability: Full documentation of steel grades (e.g., 718H, P20), heat treatment, and hardness testing.

Industries We Serve

Logistics & Warehousing: Durable block pallets, reversible designs for automated systems.

Food Processing: FDA-compliant pallets with easy-clean surfaces.

Pharmaceuticals: GMP-certified molds for contamination-free production.

Retail & E-Commerce: Nestable pallets to optimize storage space.

Sustainability-Driven Manufacturing

Eco-Friendly Molds: Design for recycled plastics (rHDPE, rPP) and biodegradable materials.

Energy Efficiency: Conformal cooling channels reduce cycle times by 15–20%, lowering carbon footprint.

Mold Refurbishment: Extend lifespan of worn molds via cavity reconditioning and component upgrades.

Why Choose Us as Your Plastic Pallet Mould Partner?

25+ Years of Expertise: 10,000+ molds delivered to 50+ countries.

Cost-Effective Solutions: Competitive pricing with bulk order discounts and 18-month warranty.

End-to-End Support: From mold design to after-sales maintenance, including troubleshooting and retrofitting.

Call to Action (CTA)

Request a Free Consultation Today!

Download our catalog or connect with our engineers to design high-performance plastic pallet molds tailored to your needs.

Leave a Reply

Your email address and tel will not be published. Required fields are marked