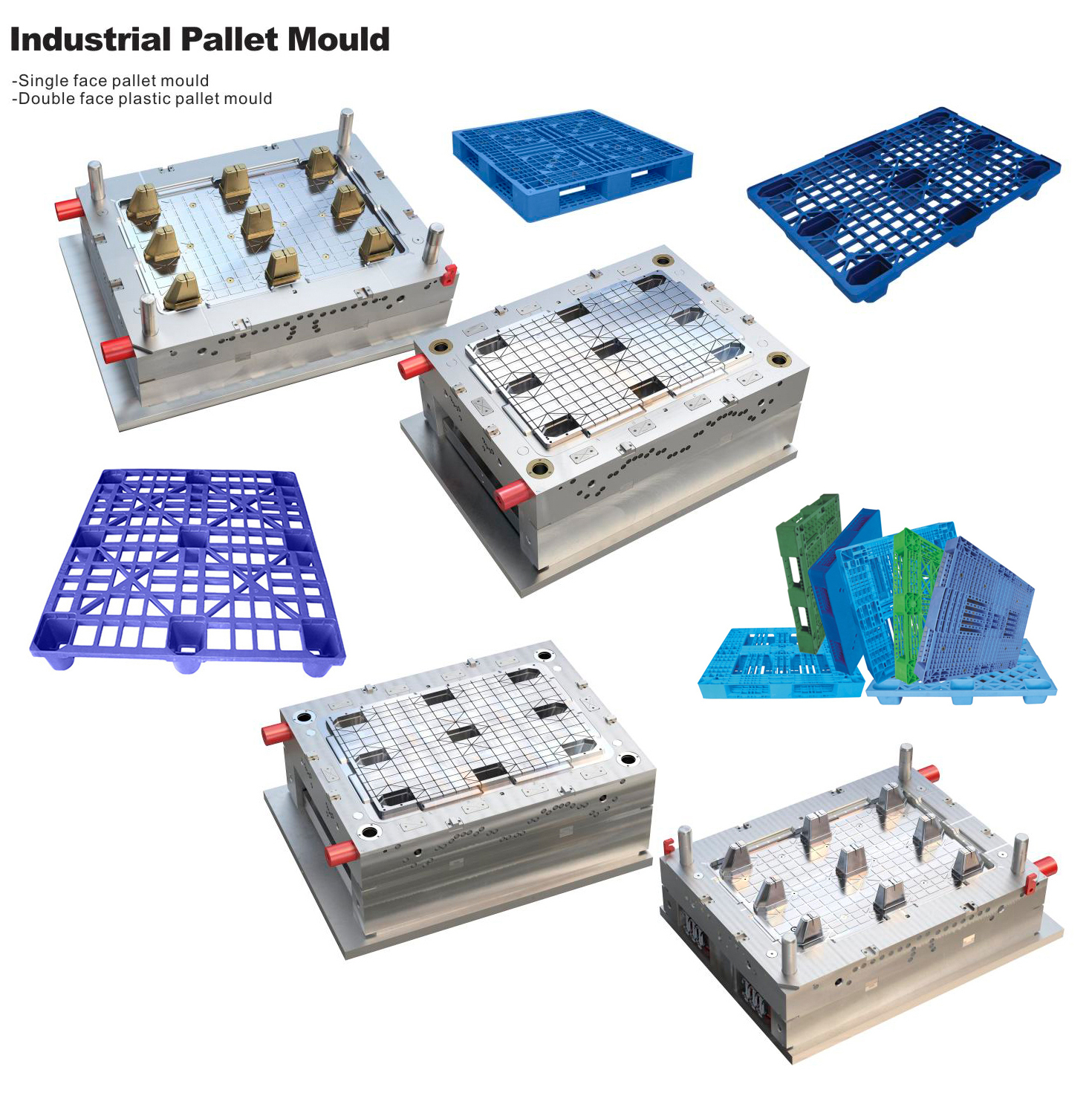

Injection Plastic Pallet Mould Manufacturer

ISM is one of the leading Chinese pallet mould companies in Southeast of China, who has been widely recognized as the professional Pallet mould company. We are specialized in manufacturing various kinds of mould, such as thin wall injection mould, dust bin mould, Home appliance mould, various bin mould, crate mould, chair mould, PET perform mould, paint bucket mould and so on.,we have a very strong and top quality mentality working team. We can offer you the good quality mould with best price.Product Description

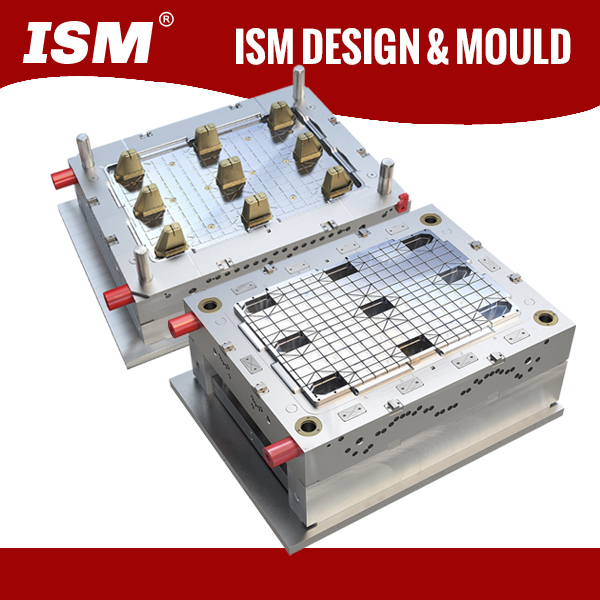

Product Name: Industrial pack pallet mould

Product material: PE

Core&Cavity steel: 718

Steel hardness: HRC34-38

Mould Standard: DME

Cavity Number: 1

Injection System: POINT GATE

Ejector System: JECTOR PIN

Cycle Time: 80S

Tooling lead time: 60 days

Mould life 500, 000 times

Quality assurance ISO9001

Our Advantage

1. High quality

2. Reasonable price

3. On time delivery

4. Good After-sale service

5. Strict quality control

6. All the mould are automotic.

Offer you:

In-time response on letters, telephone calls or fax

In-time supply the quotation and mould designs

In-time communication on the technical points

In-time sending pictures for the mould machining progress and mould finishing schedule

In-time mould test and sample delivery

In-time mould delivery.

For more information please contact us.

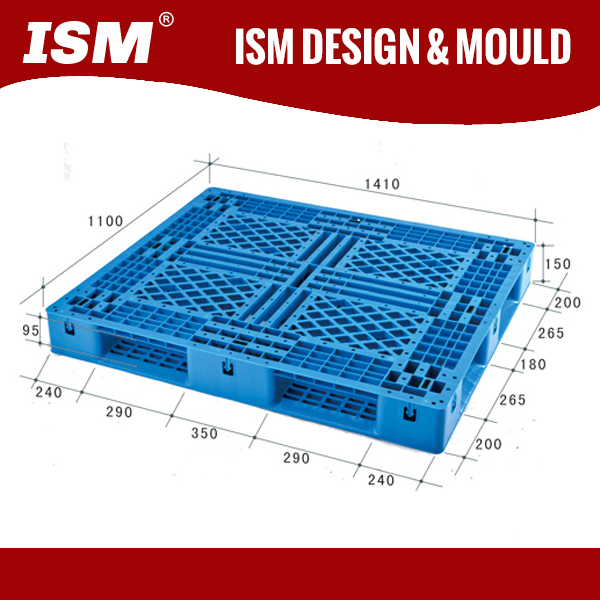

Pallet is a good product for economic development, it makes convenient for transportation. 1100x1100x150mm window type pallet have many advantages, like using hygienic plastic for raw material, which realize the green and scientific manufacturing for plastic pallet. By the way, our skid pallet owns good structure and beautiful shape, it received good reputation on the market and our customer.

| Product Name | Injection Plastic Pallet Mould |

| Product material | HDPE |

| Core&Cavity Steel | 718 |

| Steel hardness: | HRC 35-38 |

| Mould Standard | DME |

| Cavity Number | Single |

| Injection System | point gate |

| Ejector System | ejector pin |

| Cycle Time | 100s |

| Tooling lead time | 60 days |

| Mould life | 500,000 times |

| Quality assurance | ISO9001 |

| Our Advantage | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mould are automotic. | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. | |

Leave a Reply

Your email address and tel will not be published. Required fields are marked