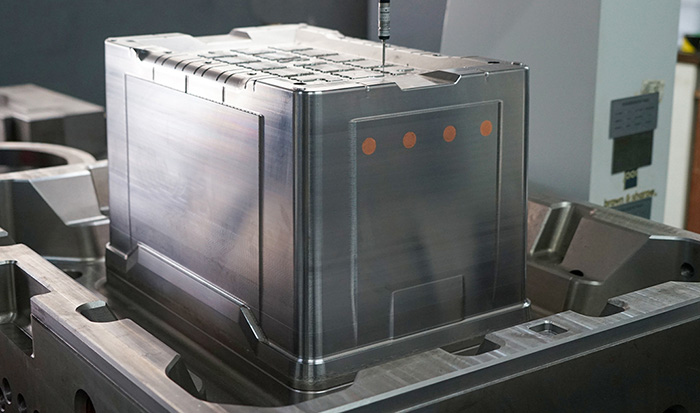

What should you pay attention to when making Crate Mould?

Making a Crate mold is a complex process involving design, processing and testing. The following are some things to pay attention to when making Crate molds:

Design specifications: When designing the mold, ensure that relevant design specifications and standards are followed to ensure that the final product meets quality and safety requirements.

Material selection: Choose wear-resistant, corrosion-resistant, and high-strength materials suitable for making Crate molds to ensure the service life and stability of the mold.

Mold structure: When designing the mold, consider the shape and size of the Crate to ensure that the mold structure is reasonable and strong to achieve efficient production.

Cooling system: Design an effective cooling system in the mold to ensure rapid cooling and maintain a stable temperature during the production process, thereby improving production efficiency and preventing mold deformation.

Easy to disassemble and clean: Consider the maintenance needs of the mold and ensure that the design makes it easy to disassemble and clean to extend the service life and ensure product quality.

Mold processing: Use high-precision CNC machine tools for mold processing to ensure the accuracy and quality of the mold to avoid problems in production.

Testing and adjustment: Before production, the mold is tested and adjusted to ensure that it can work properly and produce turnover boxes that meet specifications.

Quality Control: Establish a strict quality control process during the production process to ensure that every step meets the design requirements and standards.

Customer Needs: Ensure that customer needs are fully understood when making molds so that the design and production process can be adjusted to meet customer requirements.

Environmental considerations: When making molds, consider the environmental protection of materials and minimize the generation of waste to comply with the principles of sustainable development.

The above precautions are general and need to be adjusted according to the specific situation when making the mold. If possible, ISM Mold submits professional mold design and manufacturing for you to ensure the quality and performance of the mold.

CONTACT DETAILS

PHONE NUMBER

0086-13676642643

EMAIL ADDRESS

sales@ismmould.com

OFFICE LOCATION

No.32 Jinchuan Road , North Industrial ,Huangyan , Zhejiang , China.

Leave a Reply

Your email address and tel will not be published. Required fields are marked