Chair Mold - Mould Maker,Plastic Mold China

Chair Mould Mastery: Partnering with Expert Mould Makers in Plastic Mold China

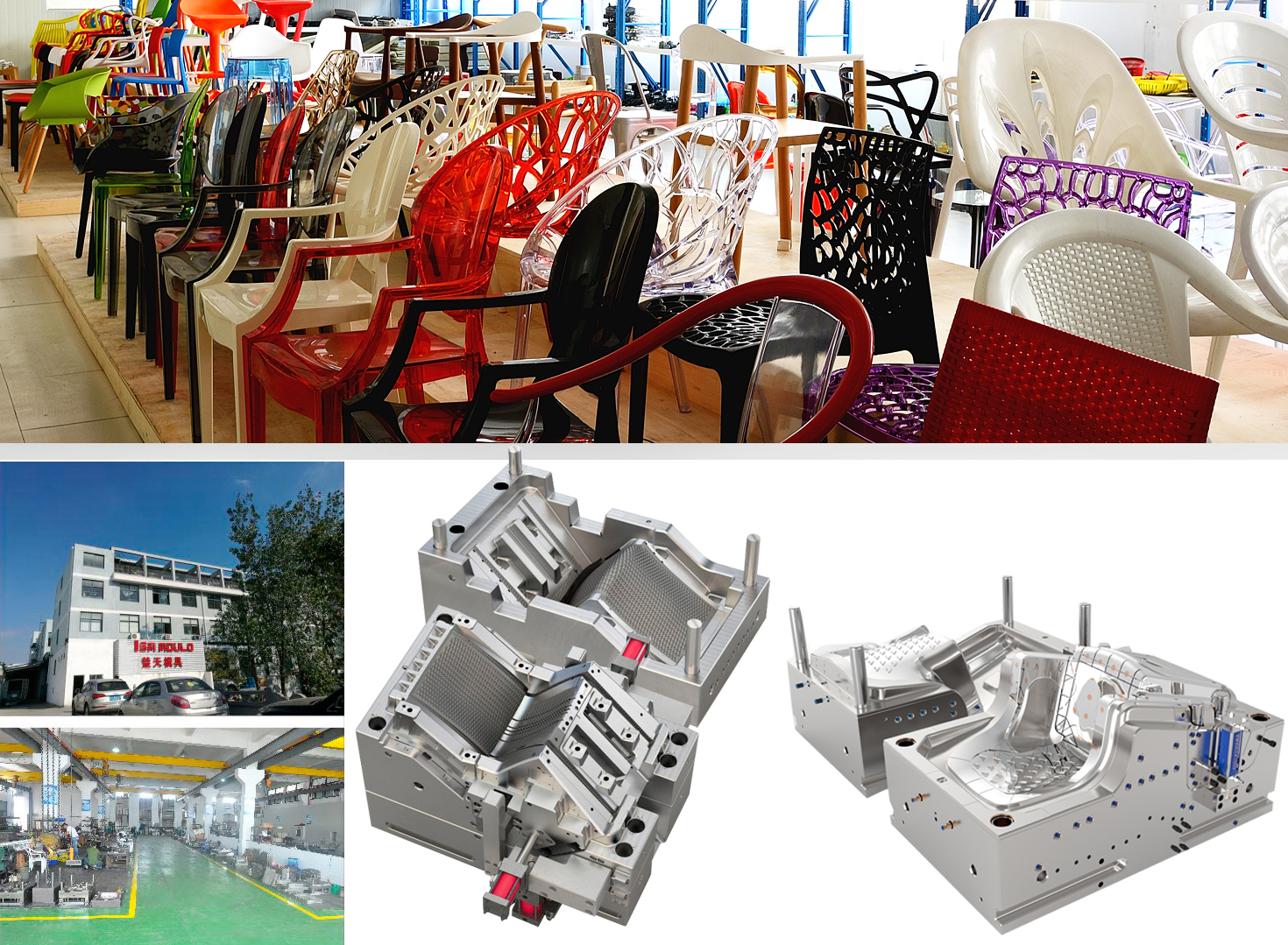

The humble chair is a daily necessity, but behind every comfortable, stylish, or durable seat lies a critical component: the chair mould. Creating high-quality, efficient, and long-lasting chairs demands precision engineering at the mould level. This is where partnering with a skilled mould maker, especially within the powerhouse of Plastic Mold China, becomes essential.

Why the Chair Mould is Foundational

A chair mould isn't just a cavity; it's the blueprint for the final product. It determines:

Part Precision & Consistency: Ensures every chair component (seat, backrest, legs, armrests) meets exact dimensions and fits perfectly during assembly.

Surface Finish & Aesthetics: Defines the texture, grain, gloss, and overall visual appeal right out of the mould.

Structural Integrity: Influences wall thickness distribution, rib design, and material flow, directly impacting the chair's strength and durability.

Production Efficiency: A well-designed mould enables faster cycle times, reduces waste, and minimizes downtime, optimizing manufacturing costs.

Ergonomics & Comfort: The mould shapes the contours that directly affect user comfort and support.

The Expertise of a Professional Mould Maker

Designing and manufacturing a top-tier chair mould requires specialized skills:

Deep Material Knowledge: Understanding how various plastics (PP, ABS, PA, Polycarbonate, composites) flow, shrink, and behave under pressure and temperature.

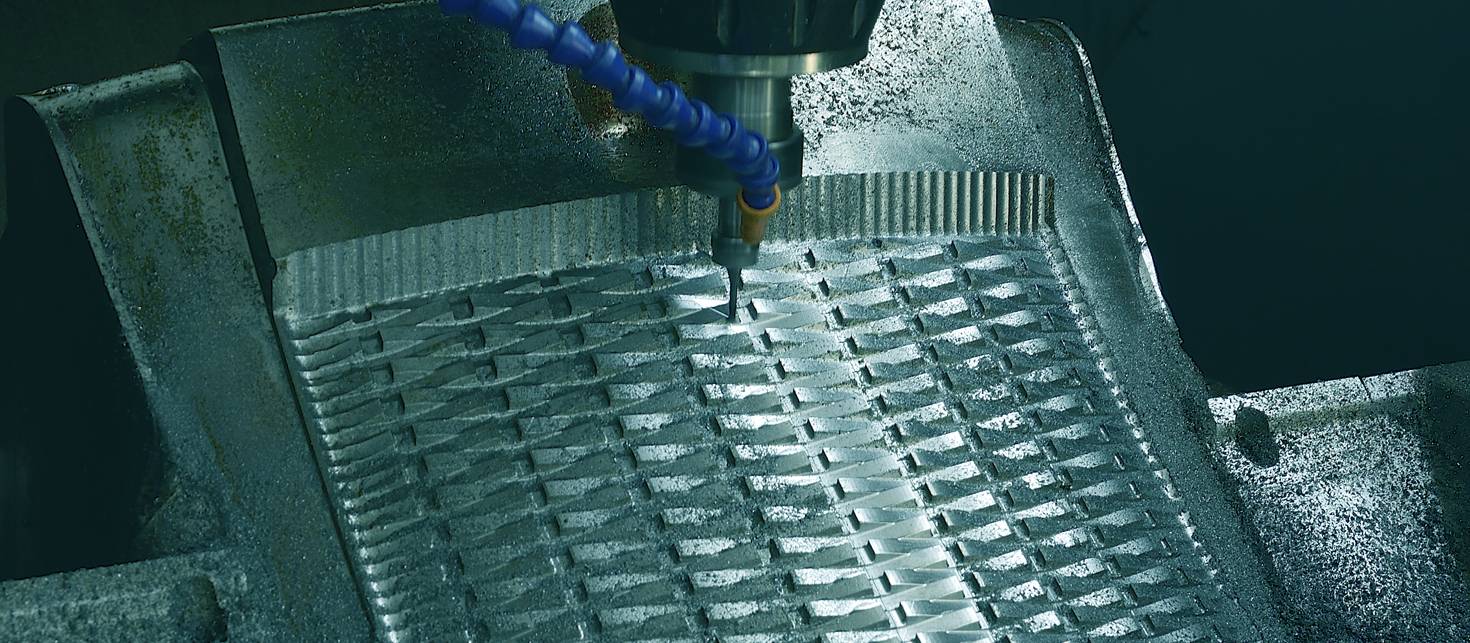

Advanced CAD/CAM/CAE: Utilizing sophisticated software for 3D design (CAD), simulation of filling and cooling (CAE - Moldflow analysis), and precision machining (CAM).

Precision Machining: Employing state-of-the-art CNC machining centers, EDM (Electrical Discharge Machining), and skilled craftsmanship to achieve micron-level tolerances.

Mould Flow Analysis: Simulating the injection process virtually to predict and prevent defects like warping, sink marks, voids, or short shots before steel is cut.

Robust Engineering: Designing moulds with efficient cooling channels, durable steel selection (P20, H13, Stainless), reliable ejection systems, and easy maintenance access.

Understanding End-Use: Considering assembly processes, stacking requirements, weight limits, and environmental factors the final chair will face.

Leveraging the Plastic Mold China Advantage

China has cemented its position as a global leader in Plastic Mold manufacturing, offering distinct advantages for sourcing chair moulds:

Unmatched Scale & Capacity: Vast networks of specialized factories handle projects of all sizes, from small boutique runs to mass production.

Advanced Technology Adoption: Leading mould makers in China heavily invest in the latest CNC machines, EDM equipment, high-speed machining, and simulation software.

Cost-Effectiveness: Competitive labour and operational costs translate into significant savings on high-quality moulds without compromising precision.

Integrated Supply Chain: Proximity to material suppliers, tool steel providers, and often the injection molding production floor streamlines the entire process.

Rapid Prototyping & Development: Many Chinese mould shops offer quick-turn prototyping (using 3D printing or soft tooling) to validate designs before committing to production moulds.

Growing Expertise in Complex Designs: Chinese manufacturers increasingly excel in complex chair moulds involving slides, lifters, unscrewing mechanisms, multi-component molding (overmolding, insert molding), and textured finishes.

Experience with Global Standards: Reputable Plastic Mold China suppliers are familiar with international quality standards (ISO 9001), material certifications, and export requirements.

Choosing the Right Mould Maker for Your Chair Project in China

When selecting your mould maker partner in Plastic Mold China, consider:

Specialization & Portfolio: Look for proven experience specifically in chair moulds and furniture applications. Review their past projects.

Engineering Capabilities: Assess their use of CAD/CAE/CAM, mould flow analysis proficiency, and design for manufacturability (DFM) approach.

Manufacturing Equipment: Ensure they have modern, well-maintained CNC, EDM, grinding, and inspection equipment (CMM).

Quality Control Processes: Inquire about their QC procedures during machining, heat treatment, assembly, and final testing (T1 sample trials).

Material Sourcing & Steel Quality: Understand their steel suppliers and grade selection for durability.

Communication & Project Management: Clear communication channels and responsive project management are vital for overseas collaboration.

Prototyping & Sampling: Confirm their process for T0/T1 samples and their ability to incorporate feedback.

Conclusion: Your Chair Starts with the Mould

Investing in a meticulously engineered chair mould from a proficient mould maker is the cornerstone of successful chair manufacturing. By tapping into the expertise, technology, and cost advantages offered by the Plastic Mold China industry, businesses worldwide can access high-quality, efficient, and innovative mould solutions. Partnering with the right Chinese mould manufacturer ensures your chairs are not only produced cost-effectively but also meet the highest standards of quality, comfort, and design, giving you a competitive edge in the global furniture market.

Leave a Reply

Your email address and tel will not be published. Required fields are marked