Precision Plastic Injection Chair Mould Manufacturers & Suppliers

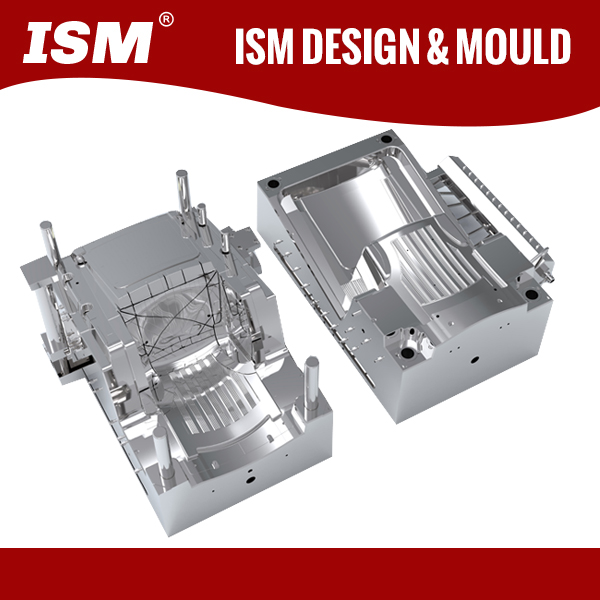

In the competitive world of furniture manufacturing, achieving consistent quality, ergonomic perfection, and cost-effective production hinges on one critical component: the plastic injection chair mould. ISM MOULD stands at the forefront as a leading plastic injection mould manufacturer and supplier, specializing in the complex engineering and precision manufacturing of high-performance moulds specifically for chairs. From sleek office task chairs to durable stackable chairs and stylish outdoor seating, ISM MOULD delivers the tooling solutions that drive success.

Why Partner with ISM MOULD for Your Chair Moulds?

ISM MOULD combines deep technical expertise, advanced manufacturing capabilities, and a dedicated focus on the unique challenges of chair mould design and production:

Specialized Chair Mould Expertise: We understand the intricacies of chair manufacturing – complex ergonomic curves, thin-walled structures, critical undercuts (seats, armrests), demanding structural loads, and high aesthetic requirements. Our engineers are experts in designing moulds for plastic chairs that overcome these challenges.

Advanced Engineering & Simulation: Leveraging cutting-edge CAD/CAM software and Moldflow® simulation, we meticulously analyze filling patterns, cooling efficiency, warpage potential, and structural integrity before steel is cut. This injection mould design optimization minimizes costly trial-and-error, ensuring manufacturability and part quality from the first shot.

Precision Manufacturing: Our state-of-the-art facility in Guangdong, China (a global moulding hub) houses high-precision CNC machining centers, EDM equipment, and expert toolmakers. We utilize premium mould steel (P20, 718, H13, S136) selected for longevity and suitability to your chosen plastic resin (PP, ABS, PA, PC, etc.), ensuring moulds capable of high-volume production runs (500,000+ shots).

Complex Solutions Mastered: We excel in implementing solutions critical for chair moulds:

Sliders & Lifters: For complex undercuts in armrests and seat bases.

Conformal Cooling Channels: Precisely follow chair contours for uniform cooling, drastically reducing cycle times and minimizing warpage – crucial for large, thin-walled chairs.

Hot Runner Systems: Minimize material waste and ensure balanced filling, especially for multi-cavity moulds or large parts. Expertise includes valve gate systems for pristine gate vestige control.

Robust Ejection Systems: Designed for reliable part release from deep draws or textured surfaces, utilizing ejector pins, sleeves, stripper plates, or air valves as needed.

Surface Finish Excellence: Whether your chair requires a high-gloss polish, a textured finish (leather grain, wood grain), or a custom pattern, our skilled technicians deliver exceptional mould surface finishing through polishing, etching (chemical, laser), or EDM texturing.

End-to-End Service: ISM MOULD is your single-source partner:

Design for Manufacturability (DFM) Analysis: Collaborative feedback to optimize part design for moulding efficiency and cost.

Prototyping Support: Assist with rapid prototypes for design validation.

Precision Mould Manufacturing: Full in-house capability from design to finished mould.

Mould Trial & Sampling (T0, T1): Rigorous testing and refinement to meet specifications.

Production Support & Maintenance: Ensuring long-term mould performance.

The ISM MOULD Advantage for Chair Manufacturers:

Reduced Time-to-Market: Optimized design and efficient manufacturing get your chairs into production faster.

Superior Part Quality & Consistency: Precision tooling ensures every chair meets dimensional, aesthetic, and functional requirements batch after batch.

Lower Part Cost: Efficient cooling, minimized scrap (via hot runners), and long mould life significantly reduce the cost-per-part.

High Production Efficiency: Robust moulds built for durability minimize downtime and maximize output.

Technical Partnership: Collaborate with engineers who speak the language of chair design and injection moulding.

Find Your Chair Mould Solution with ISM MOULD Today!

As a trusted plastic injection mould supplier and custom chair mould manufacturer, ISM MOULD is committed to delivering the tooling excellence that empowers furniture brands worldwide. We combine global capabilities with dedicated expertise to turn your chair design vision into high-quality, manufacturable reality.

Ready to discuss your next plastic injection chair mould project?

Contact ISM MOULD for a consultation and quote.

Leverage our expertise in custom plastic injection moulding, high-volume production tooling, and complex chair mould design.

Partner with a leading China mould maker focused on quality, precision, and reliability.

ISM MOULD: Engineering the Foundation for Exceptional Chairs.

Leave a Reply

Your email address and tel will not be published. Required fields are marked