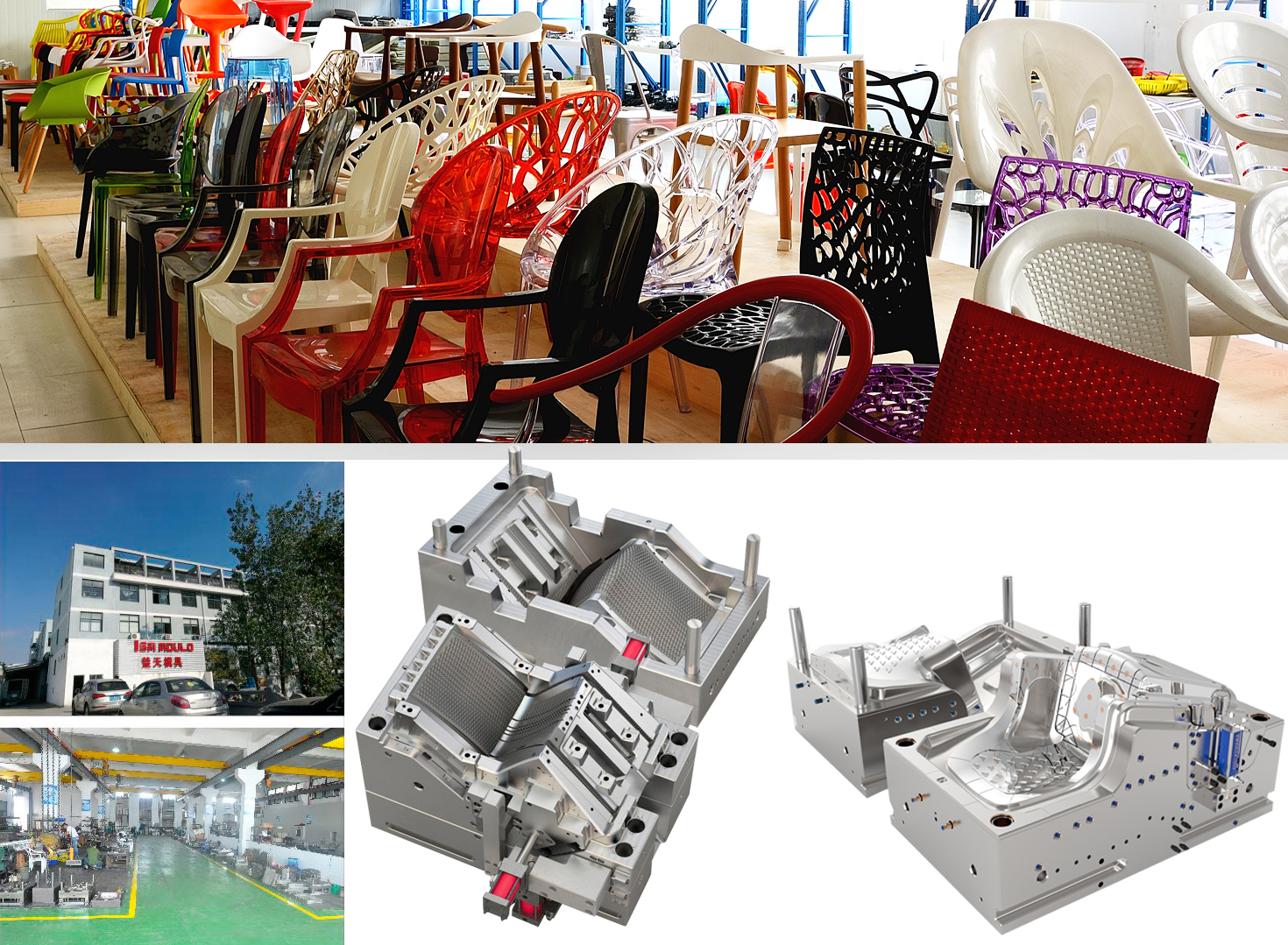

How to Improve the Quality of Plastic Chair Molds: A Guide for ISM Mould Manufacturing Factory

Introduction

Producing high-quality plastic chair molds requires precision engineering, advanced technology, and strict quality control. For ISM Mould Manufacturing Factory, enhancing mold quality can lead to better product durability, smoother production, and increased customer satisfaction. This article explores key strategies to improve plastic chair mold quality.

1. Use High-Quality Materials

The durability and performance of a plastic chair mold depend heavily on the materials used. Opt for high-grade steel, such as P20, H13, or S136, which offer excellent wear resistance and longevity. Proper material selection reduces defects like warping and premature wear.

2. Implement Advanced CNC Machining & EDM

Precision is critical in mold manufacturing. CNC machining ensures accurate dimensions, while Electrical Discharge Machining (EDM) helps create intricate details. Investing in high-precision machinery minimizes errors and improves mold consistency.

3. Optimize Mold Design with CAD/CAM Software

Using CAD/CAM software allows for better mold flow analysis, cooling system optimization, and stress reduction. A well-designed mold minimizes defects like sink marks, air traps, and uneven cooling, leading to higher-quality plastic chairs.

4. Enhance Cooling System Efficiency

An efficient cooling system reduces cycle times and prevents deformations. Conformal cooling channels can be integrated into the mold design to ensure uniform cooling, improving both production speed and product quality.

5. Strict Quality Control & Testing

Implementing strict QC measures, such as:

Dimensional inspections (CMM machines)

Surface finish checks

Trial runs with real production materials

helps detect and correct defects early, ensuring only high-quality molds are delivered.

6. Regular Maintenance & Polishing

Mold longevity depends on proper maintenance. Regular polishing, lubrication, and corrosion prevention extend mold life and maintain consistent product quality.

7. Work with Experienced Mold Technicians

Skilled technicians play a crucial role in mold manufacturing. Continuous training ensures they stay updated on the latest molding techniques and troubleshooting methods.

Conclusion

Improving plastic chair mold quality requires a combination of high-grade materials, precision machining, optimized design, and rigorous quality control. By adopting these best practices, ISM Mould Manufacturing Factory can produce superior molds that enhance plastic chair performance and durability.

Leave a Reply

Your email address and tel will not be published. Required fields are marked