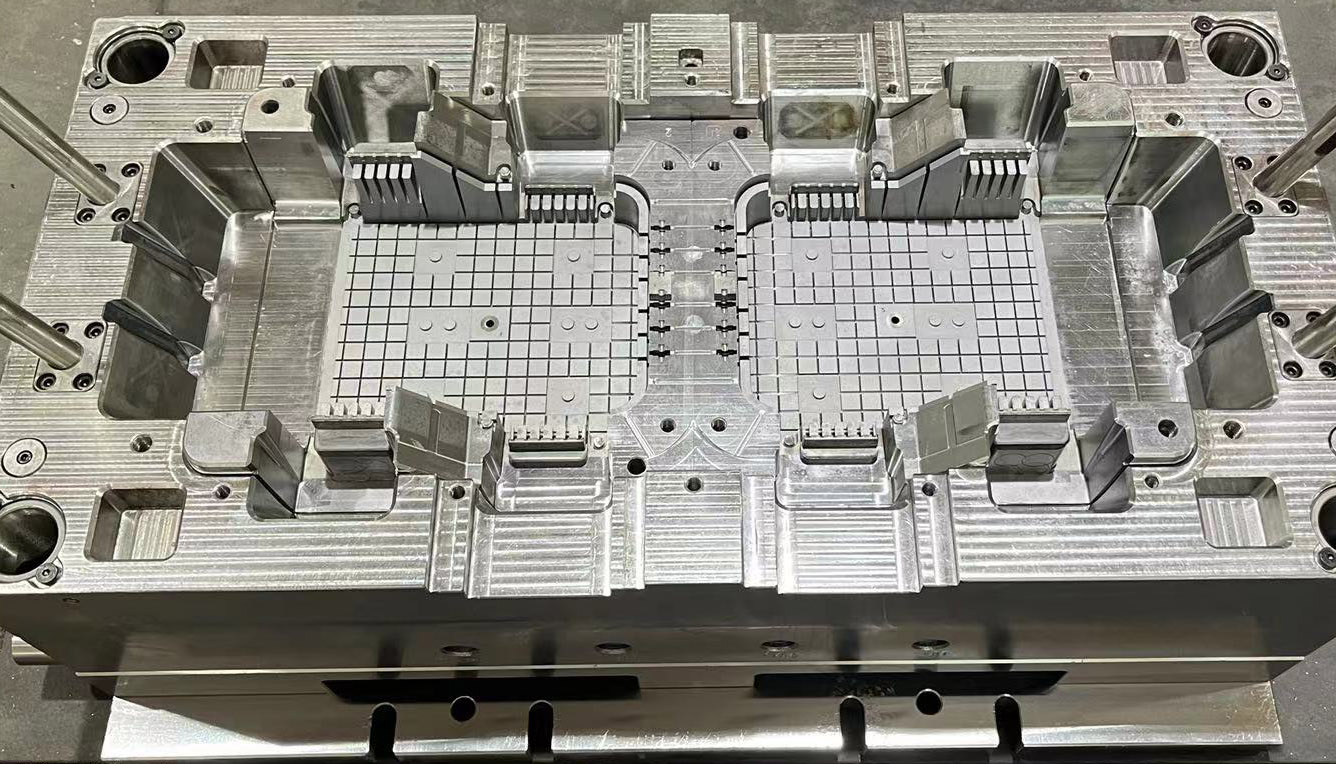

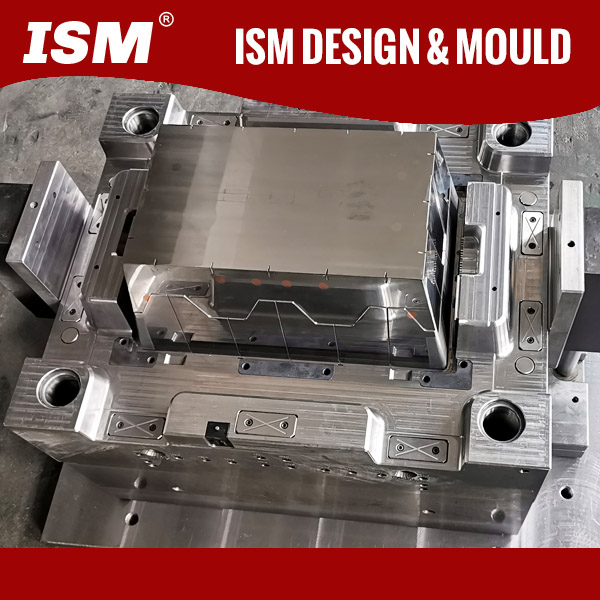

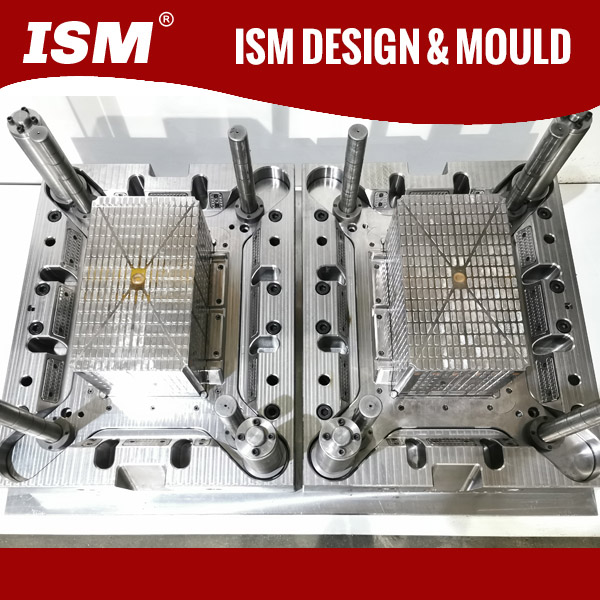

ISM Mould Plastic Crate mould structure

1. How does ISM make a Plastic Crate mould with a long service life?

The first step is to select the right steel materials for the mold base and mold core cavity. For example: to produce a four-in-one turnover box mold, pre-hardened steel with a hardness higher than 33 must be used as the mold base, and then suitable mold standard parts must be selected.

Secondly, the hardness of each piece of steel must be controlled and not too hard.

Then, the friction and guide parts of the Plastic Crate mould must be finely machined without any manual work.

Finally, some mold companies will use recycled materials for mold injection. At this time, we must consider the following two points:

A. How to ensure that small impurities in the plastic do not damage the core and cavity;

B. How to prevent impurities from entering the mold cavity.

2. How to inject the Plastic Crate mould at high speed?

A good plastic material filling system requires a special hot runner system to assist molding, because the production of durable turnover boxes requires low melt index HDPE materials, such as a melt index of 4 or 6, etc.

Ensure optimal cooling system performance. To produce a durable Crate mold, the cooling water path must be optimally designed on the largest molding surface of the mold. To produce disposable turnover box molds, quenched and tempered steel materials must be used with excellent cooling waterway design.

When choosing a high-speed injection molding machine to run the mold, the injection screw speed (RPM) must be greater than 350. Most of the world's Crate mould manufacturers use accumulators to increase the injection speed of melt.

The design of plastic turnover box mold is also very important. The ejection method of the Crate molds is best designed to be automatically ejected by the mechanical system, so that the ejection action can be completed when the mold is opened. Of course, if the injection molding machine can be equipped with two hydraulic drives to cooperate with the machine for automatic ejection, the ejection action during mold opening can be smoother.

For different types of molds, high-speed operation must be achieved. The mold must be high-precision, and the accessories must have accurate guiding functions, otherwise the mold will not be able to operate at high speed.

3. Exhaust system at the handle of the plastic Crate mold:

The exhaust at the handle of the turnover box is a very important issue, because when the turnover box is loaded with goods, the handles at both ends are the key stress points of the load. If the exhaust at the two handles on the mold is not good, obvious welding seams will be left, and the product will be easily damaged from this point.

Leave a Reply

Your email address and tel will not be published. Required fields are marked