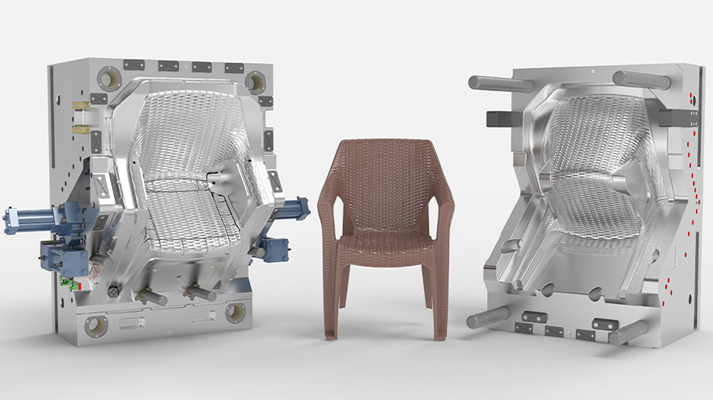

Manufacturing Plastic Chair Mold Manufacturing Process

Making plastic chair molds is a complex process involving design, manufacturing and processing. The following are the general steps for making plastic chair molds:

1. Concept design: Carry out conceptual design based on the design requirements and functional requirements of the chair. This includes determining the size, appearance, construction, etc. of the chair.

2. 3D modeling: Use computer-aided design software (CAD) to create a three-dimensional model of the chair mold. This step can help determine the shape, boundaries, and space requirements of the mold.

3. Mold design: Carry out detailed design of the mold based on the three-dimensional model. This includes separation line design, mold structure design, cooling system design, etc.

4. Mold manufacturing: According to the mold design, the metal parts of the mold are manufactured. This includes using machine tools for milling, cutting, benchwork and other processes.

5. Processing and assembly: Process and assemble the various parts of the mold. This includes performing benchwork, wire cutting, EDM and other processes.

6. Debugging and testing: After completing the mold manufacturing, debug and test to ensure the normal operation of the mold. This includes checking the opening and closing action of the mold, the injection of plastic materials, etc.

7. Mold trial and modification: Use the mold to trial the mold, and make modifications and optimizations based on the mold trial results. This helps resolve potential problems and improve mold efficiency and quality.

8. Production and Maintenance: Once the mold passes trial molding and is operating normally, mass production of plastic chairs can begin. At the same time, the mold must be maintained and maintained regularly to ensure its long-term and stable use.

Manufacturing plastic chair molds requires a variety of specialized skills and equipment. Typically requires experienced designers and moldmakers, as well as appropriate workplaces and equipment.

I hope this information helps you under

Have A Question?

Leave a Reply

Your email address and tel will not be published. Required fields are marked