Chair Mould & Plastic Molded Chair Manufacturers in China: Pioneering Global Furniture Solutions

China’s dominance in the global manufacturing landscape extends to the plastic molded chair industry, where companies like ISM Chair Mould and other leading manufacturers combine precision engineering, cost-efficiency, and sustainability to deliver high-quality seating solutions. This article explores why China remains the preferred hub for plastic molded chair production, highlighting technological advancements, customization capabilities, and the competitive edge of suppliers like ISM DESIGN&MOULD CO.,LTD and others in Zhejiang’s thriving industrial clusters.

Why Choose ISM Chair Mould and Chinese Manufacturers?

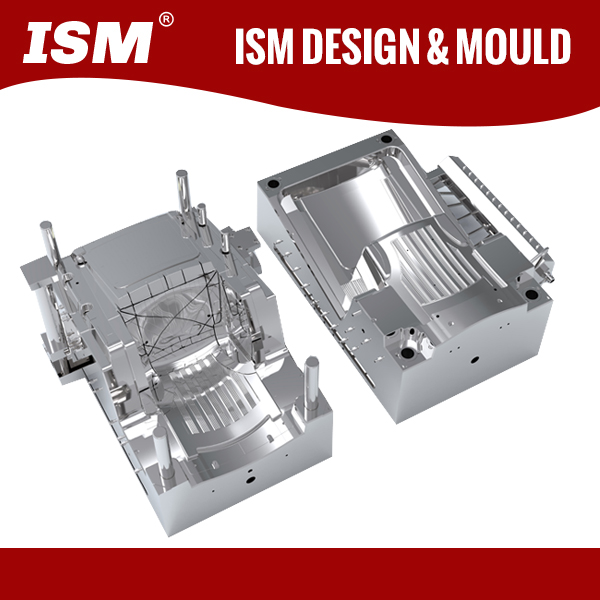

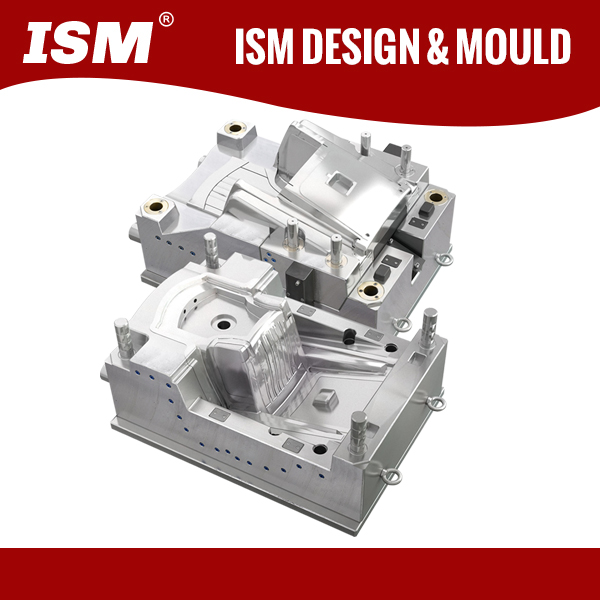

1. Precision Engineering and Advanced Technology

Chinese manufacturers leverage cutting-edge technologies such as CNC machining, Moldflow analysis, and 3D modeling

to design molds that ensure uniformity and durability. For example, ISM

DESIGN&MOULD CO.,LTD specializes in injection molds with optimized

cooling systems and materials like P20 and 718 steel, ensuring mold

lifespans exceeding 300,000 cycles 14. Similarly, companies like Sigg Mould

integrate nitrogen treatment and heat-resistant materials to enhance

surface hardness (HV850+) and reduce deformation during production 46.

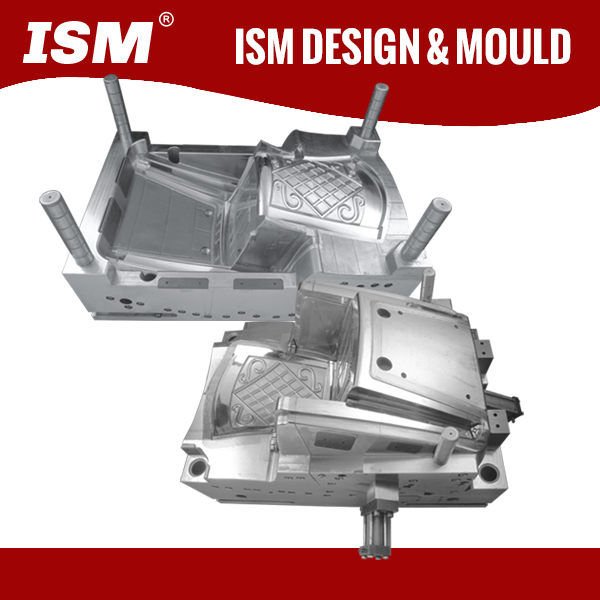

2. Customization for Diverse Applications

From stackable chairs for commercial spaces to ergonomic designs for home use, Chinese suppliers excel in customized mold development.

Jeward Mould, for instance, offers tailored solutions for indoor and

outdoor furniture, including waterproof PU foam designs ideal for humid

climates 2. These molds cater to

industries such as hospitality, healthcare, and retail, aligning with

global trends like lightweight PP furniture replacing traditional wood 28.

3. Cost-Effectiveness Without Compromising Quality

China’s economies of scale and streamlined supply chains enable manufacturers to offer competitive pricing.

ISM DESIGN&MOULD CO.,LTD emphasizes rapid production cycles and

strict quality control, ensuring timely delivery while adhering to ISO

standards 1. Additionally,

suppliers like Changzhou Haojie Mould&Plastic Co. demonstrate global

reach, exporting to markets like the U.S. with compliance to FDA and EU

regulations 10.

4. Sustainability and Material Innovation

As environmental concerns grow, Chinese manufacturers prioritize eco-friendly practices.

Modified PP and recyclable PET materials are increasingly used to

produce durable, corrosion-resistant chairs, reducing reliance on

non-renewable resources 29. Companies like Sigg Mould also implement energy-efficient cooling systems and nitrogen treatment to minimize waste 6.

5. End-to-End Services and After-Sales Support

Leading

suppliers provide comprehensive services, from mold design to

post-production maintenance. For example, Sigg Mould offers 1-year warranties and weekly progress updates during manufacturing, ensuring transparency and client satisfaction 48. This commitment to service has cemented China’s reputation as a reliable partner for global brands.

Trends Shaping the Industry

Smart Manufacturing: IoT-enabled monitoring and AI-driven design are streamlining production processes, reducing defects, and improving efficiency 9.

Lightweighting: Reducing material usage while maintaining structural integrity aligns with global sustainability goals 27.

Hybrid Molds: Combining injection and blow molding techniques to create multifunctional designs 6.

Case Study: Success Stories from Zhejiang’s Industrial Hub

Zhejiang Province, home to ISM DESIGN&MOULD CO.,LTD and Sigg Mould, exemplifies China’s manufacturing prowess. For instance:

Jeward Mould’s PP-based chairs have gained traction in Southeast Asia due to their waterproof properties and modern aesthetics 2.

Sigg Mould’s blow-molded outdoor furniture, designed for extreme durability, is exported globally via FOB Ningbo ports 68.

How to Select the Right Supplier

When partnering with ISM Chair Mould or other manufacturers, prioritize:

Certifications: Ensure compliance with ISO, FDA, or regional standards 110.

R&D Investment: Suppliers adopting Industry 4.0 technologies will future-proof your supply chain 9.

Transparency: Opt for companies providing real-time production updates and prototyping support 4.

Conclusion

China’s ISM Chair Mould and plastic molded chair manufacturers are redefining global furniture standards through innovation, customization, and sustainability. With robust infrastructure, competitive pricing, and adherence to international regulations, Zhejiang-based suppliers like ISM DESIGN&MOULD CO.,LTD and Sigg Mould offer unparalleled value. Whether for commercial, residential, or industrial use, partnering with these leaders ensures access to high-performance, eco-friendly seating solutions that meet evolving market demands.

Elevate Your Furniture Line Today! Connect with top-tier plastic molded chair manufacturers in China to explore bespoke designs and scalable production options.

Leave a Reply

Your email address and tel will not be published. Required fields are marked